Welding Equipment Meter Calibration

with meter calibration. Four topics will be covered at this time: 1. Calibration vs. Certification 2. How often is calibration necessary? 3. Resistive load vs. a welding arc 4. Calibration Equipment Source Calibration vs. Certification When you calibrate a meter, you are simply verifying that the meter is accurate within tolerances, and if

CONDUCTIVITY CHECK/CALIBRATION Clallam County

J: streamkeepers Monitoring Eqpt & supplies Calibration Maintenance SOPs Conductivity SOP's Conductivity 1 of 4 CONDUCTIVITY CHECK/CALIBRATION The YSI 85 tends to hold conductivity calibration fairly well, so calibrating at the beginning of the seasonal sampling month and checking at the end of that month should be adequate.

Daily Scale Verification Calibration International

Daily Scale Verification posted in Calibration: Hi all , I am hoping someone out there could post a procedure for performing daily checks on scales with test masses. At the moment our operators put the test mass on each corner of the scale and record that they have done this, however it doesnt look like we have a procedure to train them against.

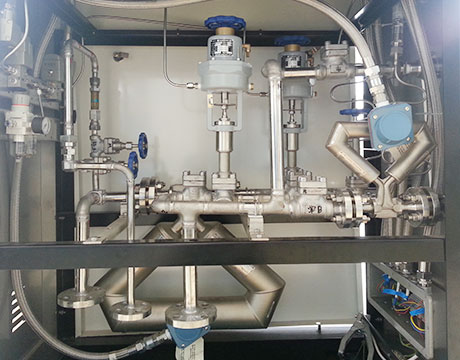

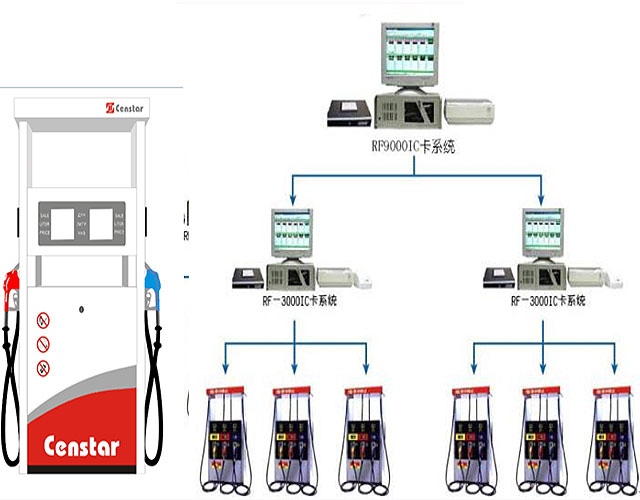

calibration of scales for sale in Nicaragua Censtar

calibration of scales for sale in Nicaragua Quick inquiry I am interested in Fuel Dispensers LPG Dispensers CNG Dispensers LNG Dispensers tank gauge system tank calibration system double layer pipeline gas/oil station management system auotomatic oil depot delivery ststem tank truck management system double layer tank skid mounted equipment

Precision Gage Calibration Systems MIC TRAC™ 4000

In House Precision Gage Calibration System MIC TRAC™ 4000 Series. The MIC TRAC™ Calibration System is an electronic, adjustable measurement center that inspects ring and plug gages, presets indicator style gages, and calibrates a variety of hand held inspection gages.

ADAS Sensor Calibration Increases Repair Costs AAA

Finally, sensor calibration is necessary when there is a related DTC in the car’s computer memory, or an automaker releases a technical service bulletin with instructions that calibration be done as part of another repair. Sensor replacement and calibration are frequently part of collision repairs.

Instruments Calibration Procedures Calibration of

Linear Instruments. The simplest calibration procedure for an analog, linear instrument is the so called zero and span method. The method is as follows: Apply the lower range value stimulus to the instrument, wait for it to stabilize. Move the “zero” adjustment until the instrument registers accurately at this point.

New Alco Sensor III Calibration Procedure Intoximeters

New Alco Sensor III Calibration Procedure. Prior to calibrating an Intoximeters breath alcohol testing instrument, you should be trained to perform the calibration functions as allowed under your specific testing program. The calibration procedures below are designed to

Weighing scale calibration How to calibrate weighing

The calibration procedure should specify where to place the load during the test and calibration results (in certificate format) should also document the locations. The test load used in an eccentricity test should be at least one third (1/3) of the max load of the weighing instrument.

Free Caliper Calibration Procedure Sample Ape Software

Detailed Procedure. Note readings when checked at zero and at the measured value of the gage block (s). If any defects have been found at this point that would affect accuracy or function of the gage, discontinue calibration and refer to section 3.6 for remedial action.

Alco Sensor IV Calibration Procedure Intoximeters

Locate the calibration tool in the carrying case of your Alco Sensor IV. The calibration tool is a small plastic peg. During the calibration procedure, the calibration tool will be used to depress the calibration switches. The switches should be pressed gently to avoid

Micrometer Calibration Standard Sets

Discover Micrometer Calibration Standards & Sets and other Micrometers at MSC Industrial Supply. Over 1 million products that ship and deliver fast.

How to Perform Pressure Gauge Calibration with a Dead

Procedure for Calibrating a Pressure Gauge with a DWT. To check the full range of the pressure gauge, repeat these 7 steps with increasing sample weights, till you reach the test device’s maximum pressure. Then, reverse the order of weights and record the downscale readings till the test device reaches 0 again.

NI 4070/4072 6½ Digit FlexDMM

Calibration Procedures The calibration process includes the following steps: 1. Initial Setup—Set up the test equipment. 2. Verification Procedures—Verify the existing operation of the device. This step confirms whether the device is operating within its specified range prior to calibration. Figure 5 shows the procedural flow for verification. 3.

NI 5122/5124/5142 Calibration Procedure National

Calibration Procedures The calibration process includes the following steps: 1. Initial Setup—Install the device and configure it in Measurement & Automation Explorer (MAX). 2. Self Calibration—Adjust the self calibration constants of the device. 3. Verification—Verify the existing operation of the device. This step confirms whether the

NI 5122/5124/5142 Calibration Procedure National Instruments

Calibration Procedures The calibration process includes the following steps: 1. Initial Setup—Install the device and configure it in Measurement & Automation Explorer (MAX). 2. Self Calibration—Adjust the self calibration constants of the device. 3. Verification—Verify the existing operation of the device. This step confirms whether the

Calibration Procedures NIST

Calibration Procedures. However, the organization of the sections and procedures on this and linked pages follows the format of the original Handbook 145, Table of Contents. Individual sections and procedures are provided to enable periodic updates of selected content as needed and to provide downloadable copy for laboratories to review, modify,

Message

Message tel

tel Inquiry

Inquiry