Alco Sensor IV Calibration Procedure Intoximeters

The procedure for calibrating an Intoximeters breath alcohol testing device will vary based on instrument model and type. Refer to the Operator’s Manual for your instrument for specific instructions on calibrating your device. DO NOT perform this procedure unless you are authorized to

In House Laboratory Services

Our qualified laboratory technicians will follow strict procedures when working on your instruments for quotes or service. Your instruments are in good hands with FlukeDirect. Once we’re ready to return your instrument, we will make every effort to communicate with you to make arrangements.

Weight Scale Calibration Procedure Example

Weight Scale Calibration Procedure. These are calibrated to NIST with an accuracy of .2%. C) Scale Accuracy: The scale is accurate to 2% for each weight. D) Scale requirements for each weight: E) Weight Scale Calibration Process: 1.0 Check the scale in this controlled environment 23°C ± 2°C and relative humidity of 40% ±10%.

Calibration Procedures

Calibration Procedures. Test Step 1. Install the 7X 1171. Transducer Adapter. A. Turn the ignition key switch to the OFF position. i01725180. Engine Speed/Timing Sensor B. Remove the timing calibration plug from the left. Calibrate. or right front face of the flywheel

Free Caliper Calibration Procedure Sample Ape Software

The purpose of this procedure is to provide general instructions for the calibration of calipers including dial, vernier, digital, or a combination thereof. Scope All calipers used to measure, gage, test, inspect and control part compliance to customer specifications and drawings.

MET/CAL® Warranted Calibration Procedures

MET/CAL® warranted procedures are optional calibration procedures for MET/CAL® Plus Calibration Software. This class of MET/CAL® procedures, produced by Fluke Precision Measurement engineers, is designed to satisfy your need for ready to go, fully tested calibration procedures.

Weight Scale Calibration Procedure Example

Weight Scale Calibration Procedure Example. Below is an example of a weight scale calibration procedure for a Sartorius Scale. It is an example only. Use the scale's manual to determine the accuracy of the scale. You select which calibrated weights to use. These weights must be traceable to NIST.

calibration scale for sale in Swaziland Censtar Science

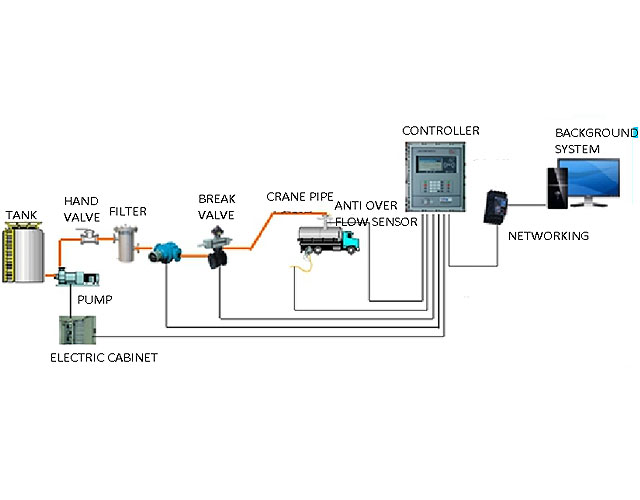

calibration scale for sale in Swaziland Quick inquiry I am interested in Fuel Dispensers LPG Dispensers CNG Dispensers LNG Dispensers tank gauge system tank calibration system double layer pipeline gas/oil station management system auotomatic oil depot delivery ststem tank truck management system double layer tank skid mounted equipment tank

Electrical Test Equipment Electrical Calibration Equipment

Transmille provide electrical calibration equipment for different services, helping your electric tester needs with our electrical test equipment.

Gage Block Calibration Quality Magazine

The frequency of calibration depends on the tolerance requirements of the job, the amount of use and conditions under which the gage blocks are used. Vantek Corp. (North Tonawanda, NY) has compiled a list of calibration procedures for gage blocks that, when tailored to meet a company's requirements, can be used as part of employee training. 1.

Alco Sensor FST Calibration Procedure Intoximeters

Below are basic calibration instructions for the Intoximeters Alco Sensor FST breath testing instrument. Unless your testing procedure dictates otherwise, a calibration is only necessary if an accuracy check has proven the instrument to be out of tolerance. Some users choose to calibrate the instrument more frequently to ensure that the instrument remains within tighter tolerances than

Calibration Procedures NIST

Calibration Procedures. However, the organization of the sections and procedures on this and linked pages follows the format of the original Handbook 145, Table of Contents. Individual sections and procedures are provided to enable periodic updates of selected content as needed and to provide downloadable copy for laboratories to review, modify,

Alco Sensor IV Calibration Procedure Intoximeters

The procedure for calibrating an Intoximeters breath alcohol testing device will vary based on instrument model and type. Refer to the Operator’s Manual for your instrument for specific instructions on calibrating your device. DO NOT perform this procedure unless you are authorized to do so. Getting Started

New Alco Sensor III Calibration Procedure Intoximeters

New Alco Sensor III Calibration Procedure. These instructions are for a Calibration procedure for Intoximeters new style Alco Sensor III. If your instrument has a serial number equal to or greater than 1200000 you should follow this procedure. Prior to calibrating an Intoximeters breath alcohol testing instrument

Calibration of temperature control and monitoring devices

• The device manufacturer specifies that a calibration procedure should be carried out at regular intervals. • Regulatory bodies require regular proof of calibration e.g. at 12 month intervals and proof of calibration cannot be provided by the manufacturer’s certificate. 1.2 Objectives

NI 5122/5124/5142 Calibration Procedure National Instruments

Calibration Procedures The calibration process includes the following steps: 1. Initial Setup—Install the device and configure it in Measurement & Automation Explorer (MAX). 2. Self Calibration—Adjust the self calibration constants of the device. 3. Verification—Verify the existing operation of the device. This step confirms whether the

NI 5122/5124/5142 Calibration Procedure National

Calibration Procedures The calibration process includes the following steps: 1. Initial Setup—Install the device and configure it in Measurement & Automation Explorer (MAX). 2. Self Calibration—Adjust the self calibration constants of the device. 3. Verification—Verify the existing operation of the device. This step confirms whether the

calibrationprocedures Google Sites

This site is intended to provide examples of basic format and content on written calibration procedures for Measurement & Test Equipment (M&TE). The information is primarily intended for organizations or individuals that do not have written calibration procedures, but it may also prove of interest for to more experienced readers.

Technical Note: Calibration Verification Practices

be established. This is done through the calibration process which is performed on every Rosemount magnetic sensor. The calibration process determines a 16 digit calibration number that is unique to every sensor. This calibration number then describes the relationship

Calibration of measuring instruments WIKA

Calibration instruments for the calibration of measuring instruments. With a calibration instrument from WIKA, pressure measuring instruments from 1 8,000 bar can be calibrated at an accuracy of % FS % of reading. With the calibration instruments for temperature, calibration of your temperature measuring instrument is possible in

MET/CAL® Warranted Calibration Procedures

Warranted calibration procedures for MET/CAL® Plus software MET/CAL® warranted procedures are optional calibration procedures for MET/CAL® Plus Calibration Software. This class of MET/CAL® procedures, produced by Fluke Precision Measurement engineers, is designed to satisfy your need for ready to go, fully tested calibration procedures.

Micrometer Calibration Standard Sets

Starrett 1 to 5 Inch Long, 5 Piece Micrometer Calibration Standard Set For Use with Outside Micrometer, Includes Case, Redemption Card for SLC Your Price: $ ea.

How to Perform Pressure Gauge Calibration with a Dead

How to Perform Pressure Gauge Calibration with a Dead Weight Tester? It’s important to calibrate pressure gauges regularly, particularly if their performance and accuracy is critical for quality assurance or matter what type of pressure gauge you use, you can perform calibration with a dead weight tester to check whether the device is performing as expected.

Procedure for Equipment Calibration and Maintenance

Procedure for Equipment Calibration and Maintenance. 1.0 Purpose This procedure specifies the schedule and requirements for calibration, performance verification, and maintenance of State Crime Laboratory testing instruments and equipment. 2.0 Scope This procedure applies to the critical laboratory equipment used by the Laboratory.

Message

Message tel

tel Inquiry

Inquiry