Costs Associated With Compressed Natural Gas Vehicle

Costs Associated With Compressed Natural Gas estimate for a specific project, contact Time fill station development costs are typically lower than those of fast fill stations, given that time fill stations generally have smaller compressors and little to no storage. Time fill stations normally use

LNG fuelling stations Linde Engineering

LNG fuelling stations Linde Engineering delivers LNG and LCNG refuelling stations supplying both liquid and compressed natural gas for vehicles. Designed and built by Cryostar, a member of the Linde Engineering Division, our LNG and LCNG refuelling stations deliver natural gas for refuelling vehicles, either in liquid or gaseous form, or combined.

LNG Plant Cost Escalation Oxford Institute for Energy

February 2014: LNG Plant Cost Escalation iv Preface Prior to 2000, LNG as a means of providing natural gas was mainly confined to markets lacking alternative supply options, and was elsewhere considered as a ‘niche’ supply source. In the early to mid 2000s this began to change as the growth in gas demand in importing regions continued and

A look at CNG station project costs Waste Today

Unless otherwise noted, the estimates for fast fill stations assume a vehicle fueling window in which 70% of the fuel is dispensed during two hours in the morning and two hours in the afternoon. For time fill stations, the compressor is assumed to run for 10 hours per day.

LNG Filling Stations Market Size 2019 Global Industry

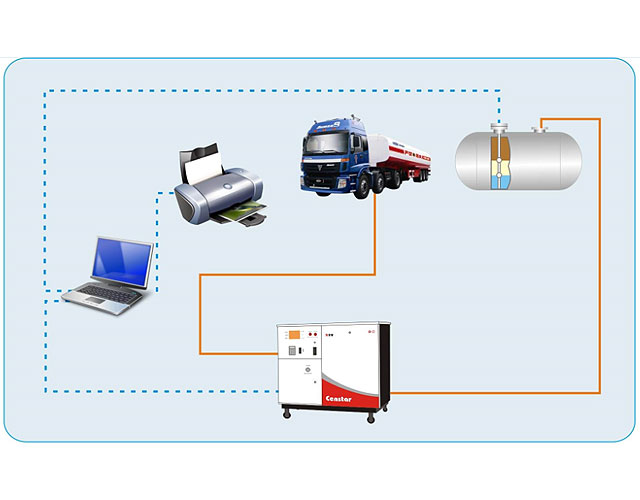

Liquefied natural gas filling stations rely on bulk delivery of fuel via tanker trucks similar to the way in which gasoline and diesel are delivered to filling stations. and the cost

5. Supply Chains for Hydrogen and Estimated Costs of

Current Technologies. For biomass technologies, both feedstock and capital costs are high, resulting in hydrogen costs greater than $ /kg. Figure 5 2 shows that for the midsize and the distributed technologies, with the exception of distributed natural gas technologies, the

Designing a CNG Fueling Station

Natural Gas Benefits Can Outweigh Costs Design and selection of a CNG fueling station is more involved than gasoline or diesel fueling stations. A properly sized and designed station will reliably serve a fleet for many years, allowing the fleet to comply with federal and local clean air mandates while enjoying the benefits of a relatively

LNG Vehicle Fueling Chart Industries

Chart vehicle fueling stations are dedicated to safely and reliably delivering fuel for all natural gas vehicles (NGV) and fleets. LNG, including liquid biogas (LBG), is typically used for heavy duty vehicles such as trucks, buses and special handling vehicles, and CNG for passenger cars and vans.

Small and medium scale LNG terminals

lng fuelled passenger ship biogas liquefaction plant lbg filling station bunkering terminal jetty reliquefaction unit satellite and bunkering terminal lng fuelled cargo ship mall/medium terminal s lng f il ng station larg e terminal regasification unit small lng carr ier lng carrier orage s & (regasification) unit (fsru/fsu) floating st oil

NGV Station Map NGV America

Natural Gas vehicle station counts continue to rise in the US, with stations now available on most highways and interstates. Whether a vehicle requires CNG, natural gas that is typically compressed at the station, or LNG, natural gas that is either liquefied on site or trucked in from a liquefaction facility, today’s drivers have many more options for refueling than even three years ago.

EUROPEAN COMMISSION DG MOVE SEVENTH LNG Blue

This opens the way for LNG (Liquefied Natural Gas), which is the way to transport natural gas by ship to any point of the globe. NG liquefies at 162º C below zero, and the cost in energy is only 5% of the original gas. This state of NG gives LNG the advantage of a very high energy content. Only 1,8 liter of LNG are

Hydrogen Station Cost Estimates NREL

Hydrogen Station Cost Estimates Comparing Hydrogen Station Cost Calculator Results with other Recent Estimates M. Melaina and M. Penev National Renewable Energy Laboratory Technical Report NREL/TP 5400 56412 . September 2013 . NREL is a national laboratory of

Total Cost Converting to CNG with CNG Station CNG

Riley said he was once quoted roughly $1,500 per month to service and repair a fast fill compressor station with 20 foot cylinders. Riley said maintenance

Building a Compressed Natural Gas CNG Refueling Station

Fast fill refueling is similar to using a gasoline or diesel pump and takes minutes to refuel. Time fill refueling is usually done overnight, in about five to eight hours. A refueling station can be installed wherever natural gas is available. Benefits of an On Site Station. Building your own CNG station can have major benefits for your

The economics of LNG —

If there are natural gas supply disruptions or if the winter of 2008/2009 is colder than expected, the price of LNG may for a time go higher than the price of oil on a BTU basis. The 2007/2008 winter demonstrated the potential for large weather related LNG demand spikes. So far this article on the economics of LNG.

4 Project Structure, Cost, and Financing

Liquefied natural gas (LNG) projects are ex pensive. The total capital required for aworld scale ventureinvolving 1 billion cubic feet per day (Bcf/d) beginning in the early to mid 1980s is nearly $.5 billion ( 1978 dollars). Approximately 40 percent ofthis cost is applied to the gas pro duction and liquefaction facilities in the export

cng filling station cost in uzbekistan Censtar Science

Total Cost Converting to CNG with CNG Station CNG Many fleets and municipalities are not making a commitment to use natural gas as a transportation fuel because the fleet managers do not have enough information to accurately estimate the total cost converting to CNG including CNG vehicle conversion, CNG fueling station development and all other tasks and costs associated with the process.

LNG BC D 3 8 Cost analysis of LNG refuelling stations

EUROPEAN COMMISSION DG MOVE. SEVENTH FRAMEWORK PROGRAMME GA No. 321592 Cost analysis of LNG refuelling stations. LNG Blue Corridors Project is supported by the European Commission under the Seventh Framework Programme (FP7). The sole responsibility for the content of this document lies with the authors.

Message

Message tel

tel Inquiry

Inquiry