Tank Gauging & Inventory Management Solutions Overview

Tank Gauge Guided Wave Antenna Planar Antenna (Stilling Well) Small Horn Antenna Parabolic Antenna Horn Antenna Rod Antenna Tank Gauging Loop Communications Tank Side Communications Wireless Communications Independent Communications Float & Tape Tank Gauge . Servo . Custody Transfer Tank Gauging Float & Tape Gaugeboard . Instrumentation and Sensors

Servo tank gauging instrument Proservo NMS5 Endress+Hauser

The intelligent tank gauge Proservo NMS5 is designed for high accuracy liquid level measurement in custody transfer and inventory control applications. It fulfills the exact demands of tank inventory management and loss control and is optimized in regards of total cost saving and safe operation.

Inventory management so much more than just measuring

Inventory Management Solutions. Inventory Management Solutions help you to reduce inventory costs, improve customer satisfaction and increase productivity. Unlock the true potential of your supply chain. Supply chain solutions. It is often a long way for the data of measuring points on tanks to where the information is needed in the ERP system.

Successful Tank Farm and Terminal Management It starts

4 uccessful Tank Farm and Terminal Management Your benefits • Higher accuracy and higher safety give you more control • Common design components reduce complexity, commissioning and spares • Simplicity, uniformity and efficiency across all field instrumentation Our new platform of high performance tank gauging

Tank farms and terminals Auxiliary Plants in the

State of the art tank farm automation and terminal management means much more than simply monitoring and controlling liquid flows, filling levels, pumping performance, energy consumption, or

Storage Oil & Gas Siemens

Siemens storage solutions can simplify tank farm and terminal operations and reduce operating costs. Our goal: integrated, flexible, and cost effective storage solutions Siemens solutions include the full scope of rotating and electrical equipment needed to operate the facility.

TANK GAUGING EQUIPMENT

Tank Gauging Tape, "Double Duty" (14) Tank Gauging Tape, Chrome Plated (8) Tank Gauging Tape, Etched Black (6) What is the difference between a Factory Certification and a NIST Certification on dead weight testers and gauges? Are replacement parts available for all RSC products?

Typical P&ID arrangement for Storage Tanks EnggCyclopedia

Typical instrumentation on the tank would be level gauges and transmitters plus pressure gauge and transmitters. For tank under continuous operation a level control valve has to be provided as indicated in the sample drawing. For tank with blanketing gas a self regulating pressure valve has to be provided on the blanketing gas inlet line.

On farm Fuel Storage Michigan Agriculture Environmental

If the ground water discharges to surface water, the contamination will be discharged to the surface, too. Fuel residues in the soil may be moved downward through the soil profile by rain and melting snow. Contamination of groundwater can continue for many years from a leak or spill.

Storage tanks, Fixed roof tanks, Floating roof tanks

The most common tank type is the full containment tank. Tanks are roughly 55 m (180 ft) high and 75 m in diameter. In LNG storage tanks if LNG vapours are not released, the pressure and temperature within the tank will continue to rise. LNG is a cryogen, and is kept in its liquid state at very low temperatures.

Optimal Tank Farm Operation Carnegie Mellon University

A tank farm is a set of storage tanks that hold finished product until it is shipped. Each tank can only hold one Loading of product takes place only from storage tanks product. Dedicated Tanks! Without available storage space. Material flow diagram used for the tank farm.

Tank farms and terminals Auxiliary Plants in the

A key task of tank farm management is configuring, controlling, and monitoring material transport through pipe networks. A fluid or gaseous medium must be transferred from a defined source to a defined destination. This task, which often requires highly sophisticated algorithms, is

PowerPoint: Module 7 Tank Farm and Bulk Storage Fire

Module 7: Tank Farm and Bulk Storage Fire Incidents * Objective Upon the successful completion of this module, participants will be able to develop plans to fight or contain fires at tank

The Oil & Gas Supply Chain: Oil Tank Storage and Movement

Oil Movements Are Complex. With best practices, the topology of the piping system is precisely known and understood by the tank farm automation system. The status of the piping system, block valves, control valves, and all pumps must be known. Supply chain planning must consider any leaking valves or defective pumps,

The Basics of Setting Up An Oil & Gas Production Tank Battery

The Basics of Setting Up An Oil & Gas Production Tank Battery. The tank battery is the arrangement of storage and processing tanks, flow lines, and other equipment necessary to operate a well. Some tank batteries are connected to just one well, while others receive

L&J engineering Level Gauging, Tank Management, and

L&J engineering Tank Level Gauging Solutions for Bulk Storage When precise level measurement is critical, L&J engineering is the clear choice. As an industry leader in level gauging solutions for over 35 years, L&J engineering's product offering continually evolves to meet changing bulk storage needs.

Petroleum Tank Farms, engineered, designed, fabricated

Petroleum Tank Farm Design, Manufacturing and Installation is Critical for Cost Control and Compliance When Multinational Refineries Need Petroleum Tank Farms, they Choose 1 Stop, You Should Too! Petroleum tank farms should only be designed by qualified engineers.

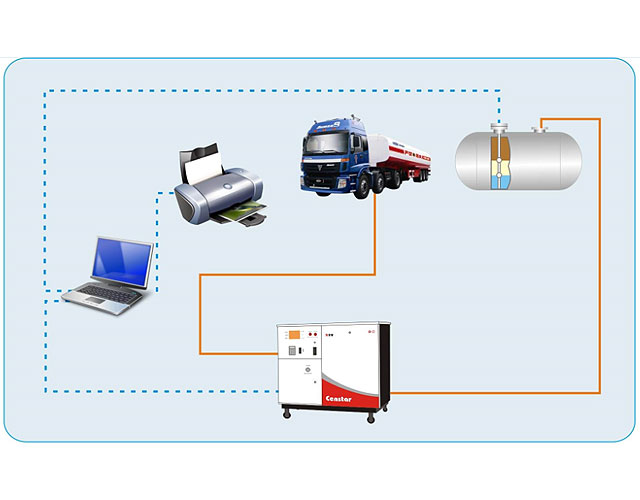

Tank Farm Terminal Management For Measuring Monitoring

Tank Farm Terminal Management For Measuring Monitoring Loading Offloading Liquid,Oil Inventory Management System , Find Complete Details about Tank Farm Terminal Management For Measuring Monitoring Loading Offloading Liquid,Oil Inventory Management System,Tank Farm Terminal Management,Quantitative Loading System,Oil Loading Offloading System from Chemical

Tanks Dairy Processing Handbook

Tanks in a dairy factory are used for a number of purposes. The sizes range from 150 000 litres for the silo tanks in the reception department down to approximately 100 litres for the smallest tanks. Tanks can generally be divided into two main categories according to function: Storage tanks; Process tanks; Storage tanks Silo tanks

Tank Farm Management ASTM International

Tank farm management, floating roof tanks, fixed roof tanks, tank quality tracking system, marine terminal, truck terminal, wagon terminal, storage tanks, oil movement and storage system, tank gauging system, tank farm design, tank inventory. Author Information: Agrawal, Suresh S.

Atlanta Flow Systems, Inc. Varec Tank Gauging

Varec Tank Gauging. Tank Gauging Products for Bulk Liquid Storage Tanks Every company that operates a tank farm, terminal, refinery or bulk storage facility has its own business requirements for managing bulk liquid petroleum assets. Meeting these requirements, while selecting the best technology and systems for the given application,

Emerson integrates gauging system and wireless for tank

Many tank storage facilities that could benefit from modern, non contact gauging currently use obsolete signal wiring, or are not connected from the tank storage area. Retrofitting an obsolete gauging system is expensive and time consuming because the distance between storage tanks and the control room can be more than one kilometer, requiring extensive trenching and cabling.

Common Tank Gauging Technologies and How They Work Varec

Float and Tape Tank Gauging. These instruments have been the liquid level measurement technique of the petroleum tank gauging market for over 90 years due to their simplicity, reliability and cost. Varec’s float and tape tank gauge solution consists of a 2500 ATG selected for the appropriate tank type. The instrument provides a measurement to

FUELING AND FUEL MANAGEMENT/STORAGE FUEL

FUELING AND FUEL MANAGEMENT/STORAGE FUEL TRANSPORT AND TRANSFER TANK TRUCKS. 1. Version, Date. 2, 10 March 14 (EMS) tanks at the Bulk Fuel Farm. Fuel truck drivers may be Bulk Fuel Farm (G 4), MCAF and HMX 1 truck drivers, or commercial providers. and uses the automatic tank gauge (ATG) to get a factor and the net gallons. The fuel

Tank Farm Operations and Performance Training

Tank Farm Operations and Performance training in London (UK) , Dubai (United Arab Emirates) , Kuala Lumpur (Malaysia) , Istanbul (Turkey) , France (Paris)

Terminals and Tank Farms Vansad Automation

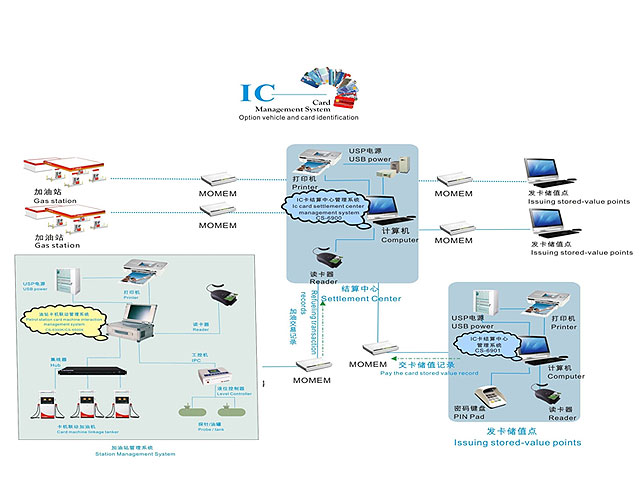

The Tankvision Tank Scanner connects multiple tank gauges via one field loop. It can handle a maximum of 15 tanks. Several gauge protocols are supported. Most used are: • Serial Modbus • Sakura V1 Optionally, the Tank Scanner can be equipped with a full set of tank inventory calculations. The calculations are based on various

Tank Inventory Systems Honeywell

Tank Inventory Systems offer open connectivity for various field protocols that enable the seamless integration of existing field equipment. A set of standardized host interface areas are available to link Entis packages to control systems and business domain packages for advanced resource planning and asset management.

tank farm management German translation Linguee

Besides powerful analysis, archiving, and programming functions, PSIcontrol/Oil also includes functionalities such as leak detection and localization, tank farm management, pump optimization, recording of load changes and a training system.

Level measurement: General process tank level vs

inventory value of $7,536. For a tank farm with 20 tanks this could be $150,720 of product discrepancy that must be accounted for. Custody transfer tank gauging Within this tank gauging segment there are some applications where extremely high accuracy measurements are required and these are characterized as custody transfer tank gaging. These are

What is a Tank Farm? Definition from Corrosionpedia

A tank farm is an area used mostly for the storage of oil and/or petrochemical products in large tanks. From the tank farm, petroleum products are distributed to end users or further storage facilities. Tank farms consist of: Tankage, either above ground or underground

The Basics of Setting Up An Oil & Gas Production Tank Battery

The Basics of Setting Up An Oil & Gas Production Tank Battery Blog Greg Archbald The tank battery is the arrangement of storage and processing tanks, flow lines, and other equipment necessary to

Tank gauging Endress+Hauser

Tank gauging Controlling and monitoring of the inventory of your tank with highest accuracy level instrumentation Monitoring and control of bulk liquids during processing, transportation and storage is

An Intensive 5 Day Training Course Tank Farm Operations

terminals and tank farms, methods of tank gauging, crude oil product specifications, product blending and tank mixing, dealing with of oil spill emergencies, cleaning of

Tank Farm Operations and Performance PetroKnowledge

The tank farm’s mission is to perform its daily operations while maintaining a safe storage terminal. Attendance of this five day training course will ensure: In depth knowledge of operations & management of crude oil and product terminals. Apply proper planning and scheduling techniques in storage

TAS Solutions Tank Gauging and inventory management

• High accuracy tankage monitoring, inventory management in both volume and mass with the precise measurements of the level, temperature, density and the oil water interface of the liquid in tanks; • High high level and low low level alarming;

UIDANCE FOR NDERGROUND TORAGE ANK ANAGEMENT AT

operating manuals and/or your state UST management requirements for complete requirements in your area. GUIDANCE Calculate the difference between the closing gauges and opening gauges and compare with the amount shown on the invoice; (2) Check the tanks for water at the opening of business following An automatic tank gauging (ATG

level measurement and tank gauging systems SlideShare

Tank Gauging System • A generic name for the static quantity assessment of liquid products in bulk storage tanks • Data from Gauging Instrumentation transmitted to Inventory Management System to compute overall state (level, mass, density, volume) of Product inside the tanks.

Terminal management system for oil & gas OpenTAS TMS

Terminal management system: Simplifying previously complex business processes. Three key challenges many tank terminals and refineries face are to reduce operating costs, ensure smooth IT processes and increase safety and security. OpenTAS TMS is a powerful Terminal Management System that optimizes and automates all logistic and administrative processes in terminals and refineries.

Tank vs Dipstick What's the difference? WikiDiff

As nouns the difference between tank and dipstick is that tank is a closed container for liquids or gases or tank can be a small indian dry measure, averaging 240 grains in weight while dipstick is a stick or rod used to measure the depth of a liquid often used to check the level at which a liquid in an opaque or inaccessible tank or reservoir stands; gauge.

Tank Inventory Management Software RTG

Hybrid tank gauging With a high accuracy hybrid tank gauging system the need for manual density sampling is eliminated. With tank gauging data such as level, pressure and temperature you get automatic density measurements and mass calculations from the TankMaster system. The density measurements are made in real time just like the level measurement.

Level measurement: General process vs. inventory tank

For inventory tank gauging applications, level, temperature, and sometimes pressure (for density calculations) measurement instruments are employed. Common technologies include radar, guided wave radar, and sometimes pressure measurement transmitters. These technologies can provide accuracy of ±2 to 3 mm and better.

DNR bags Automatic Tank Gauging & Tank Farm Inventory

Tank farm management and bulk inventory management solutions provider DNR Process Solutions has won a contract for automatic tank gauging system from PT SMART for their palm oil tanks

Successful Tank Farm and Terminal Management It starts

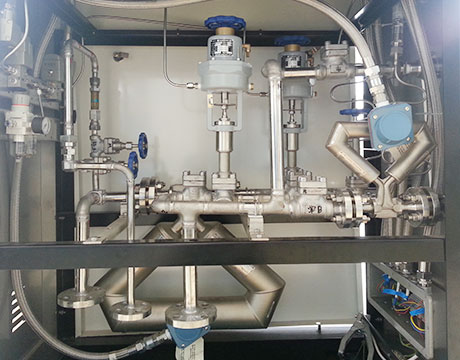

Besides the tank gauging devices we offer process instrumentation and software packages for all the tasks in your tank farm or terminal: Pressure, flow and temperature devices, loading metering skids as well as data interfaces and our inventory management software solutions Tankvision®, Terminalvision® and SupplyCare®.

Terminals and Tank Farms Vansad Automation

Terminals and Tank Farms Flow measurement and tank gauging solutions for custody transfer and inventory control Every loading contract includes a paragraph about the difference between onshore figures and tanker figures. Typically, a difference It can handle a maximum of 15 tanks. Several gauge protocols are supported. Most used are

Successful tank farm and terminal management Endress+Hauser

Successful tank farm and terminal management Our instrumentation and software solutions for your success Our new tank gauging instruments measure product levels with highest accuracy and reliability in every tank, and with the technology that fits best.

Message

Message tel

tel Inquiry

Inquiry