Fleet Solutions: Tips for Designing a CNG Fueling Station

Compressed natural gas (CNG) is considered one of the cleanest, safest and lowest cost vehicle fuels, and it's produced in North America.However, it isn't as simple to handle as conventional fuels such as gasoline and diesel. Not only are there added vehicle costs, the decision to construct a CNG fueling station is a major factor in switching a fleet.

Expansion of hybrid LNG and CNG fueling stations

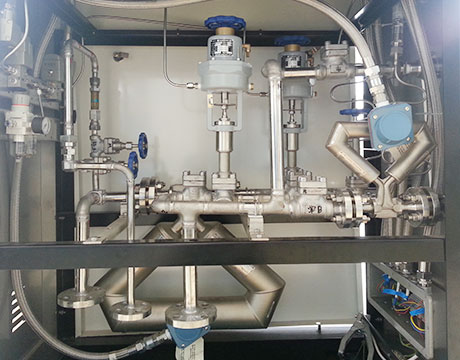

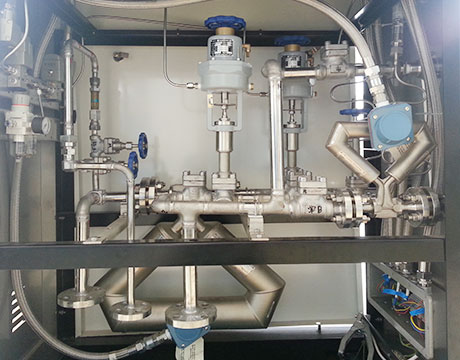

LNG fueling stations are superior in terms of equipment, operating costs and safety. However, LCNG stations fill the demands of fueling for both LNG and CNG vehicles. LCNG refueling stations compress the LNG up to 300 bar pressure, and then the pressurized liquid is vaporized and heated for conversion into regasified LNG.

Costs Associated With Compressed Natural Gas Vehicle

various sizes and types of CNG fueling stations and an overview of factors that contribute to the total cost of an installed station. The information presented is based on input from professionals in the natural gas industry who design, sell equipment for, and/or own and operate CNG stations.

Building a Compressed Natural Gas CNG Refueling Station

A refueling station can be installed wherever natural gas is available. Benefits of an On Site Station. Building your own CNG station can have major benefits for your operation. Fuel production control. With your own station, you know that you'll have CNG available exactly when and where you need it, and with the capacity you need. Cost.

CNG Energy Solutions Real Time Data and Personal Support

Costs Control maintenance and operations. Many CNG stations are unmanned, and keeping them operational for uninterrupted fueling for customers’ fleets can be a considerable challenge. The costs associated with unplanned outages and downtime can be prohibitive.

Alternative Fuels Data Center: Compressed Natural Gas

Compressed Natural Gas Fueling Stations Unlike gasoline or diesel stations, compressed natural gas (CNG) stations are not "one size fits all." Building a CNG station for a retail application or a fleet requires calculating the right combination of pressure and

NGV Station Map NGV America

Time fill stations have significantly lower equipment and installation costs because they do not require storage, priority, or sequential refueling components. These types of stations are generally “behind the fence” operations not open for fueling by the public.

CNG Fueling Equipment Clean Energy Compression

Compression Equipment. Compressed Natural Gas (CNG) offers cleaner, cost efficient energy, particularly as an alternative to diesel or petroleum fuel. Clean Energy Compression offers CNG compressors for a full range of requirements from highly scalable and reliable to ultra portable solutions.

Total Cost Converting to CNG with CNG Station CNG

Compression equipment operating costs include electrical, CNG gas to run the compressor, and associated maintenance costs such as parts, oil, and filters. Riley said he was once quoted roughly $1,500 per month to service and repair a

CNG Fueling Station Maintenance CNG fueling stations

The amount of the penalty should be proportional to the cost and inconvenience of not having the fueling station operational when needed to fuel vehicles. Other Helpful Links to Get More Info About CNG Fueling Station Maintenance.

Creating a CNG Station CNG Now Vehicles, Stations & News

It may provide partnerships and collaborations that can lower your costs. There are many other details that need to be addressed when building a CNG filling station or adding CNG to an existing location. Be sure your refueling equipment provider can address all details and needs.

Designing a CNG Fueling Station

Not only are there added vehicle costs, but the decision to construct a CNG fuel station is a major factor in switching a fleet. CNG fuel stations are a significant capital and operating commitment that should be given full consideration before purchasing decisions are made.

A look at CNG station project costs Waste Today

The estimated cost ranges for various sizes and types of CNG fueling stations and a variety of other factors contribute to the total cost of a completed fueling station. The most significant costs associated with developing a station are those related to land, engineering drawings, station design, equipment, and construction.

Septem Clean Cities: Building Partnerships

Are a cost effective fueling option that allow vehicles to conveniently refuel overnight or when the vehicles are parked and not in use. Time Fill CNG Station

Transit Company adds CNG Bus and Fueling Equipment

Transit Company adds CNG Bus and Fueling Equipment BeST Transit acquires new CNG Bus and equipment for CNG fueling station. The single tower dryer, an integral component to remove moisture from the natural gas, is being set in place at the Dandi Mart site in Sayre, Pennsylvania.

Preventive & Repair Maintenance CNG Stations

MWES’s preventive maintenance is designed for the specific equipment at each CNG station site. The following is a summary of some of the maintenance tasks MWES is providing as part of an all inclusive maintenance at a customer owned CNG station: Relieve crankcase pressure, check compressor oil level, add oil if necessary, remove used oil

Fueling Station Design and Build Trillium CNG Home

We design our systems in such a way that the equipment won’t be pushed to the edge daily. This ensures that operating temperatures and other stressors stay within standard operating parameters. Overall, Trillium built stations last longer saving you money and providing peace of mind.

LNG Vehicle Fueling Chart Industries

Chart vehicle fueling stations are dedicated to safely and reliably delivering fuel for all natural gas vehicles (NGV) and fleets. LNG, including liquid biogas (LBG), is typically used for heavy duty vehicles such as trucks, buses and special handling vehicles, and CNG for passenger cars and vans.

Technology and Equipment Clean Energy Fuels

No matter what type of station fits your needs, Clean Energy ensures that station equipment and the technology that powers and maintains it will be state of the art and second to none. In fact, Clean Energy has set the industry standard for virtually every aspect of the natural gas vehicle fueling process.

By Clean Fuel Connection, Inc. BAAQMD

The electricity usage for the station was 165000 kWh per year (or 654 kWh per weekday) at a total cost of $31,618 for a cost per kWh of $.19. Looking at it on a per gallon basis, each gallon of CNG costs $.11 of electricity to If we assume a $.12 per kWh rate,

Message

Message tel

tel Inquiry

Inquiry