FLNG Technology LoneStar LNG

The liquefaction vessel is based on a standard Moss type LNG carrier of 155 170,000 m3 capacity and equipped with Dual Fuel Diesel Electric (DFDE) propulsion. The Moss containment system eliminates risk of damage from sloshing in slack tanks during filling.

LNG / CNG

LNG and CNG are genuine alternatives. It is used as fuel in vehicles, such as taxis and buses. LNG is used as a fuel for trucks and buses, and ever more frequently as the gas supplying industries and regions where there is no adequate pipeline supply. CRYOTEC constructs liquefaction plants that produce LNG.

Slovenia gets first LNG filling station LNG World News

Slovenian company Energetika Ljubljana said it had opened the country’s first liquefied natural gas (LNG) filling station for trucks as part of a plant to reduce carbon emissions. The construction of the LNG station located in the Slovenian capital, Ljubljana, is a Slovenian Spanish partnership project involving companies Enos, Energetika Ljubljana and HAM Criogénica.

LNG plants Reversed Brayton cycle Liquefaction

LNG plants Reversed Brayton cycle liquefaction. REVERSED BRAYTON CYCLE THE RELIABLE SOLUTION FOR SMALL SCALE LIQUEFACTION . Wärtsilä’s larger liquefaction plants are easy to operate, reliable, and fully automated. They represent a low lifecycle cost solution in the small to medium size liquefaction capacity range.

LNG fuelling stations Linde Engineering

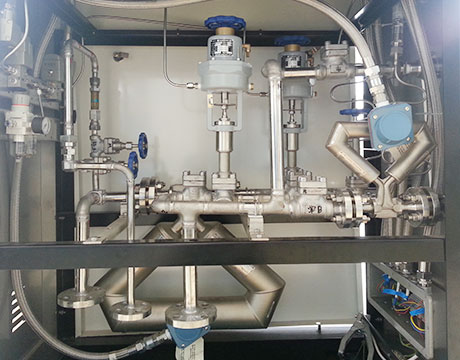

LNG fuelling stations Linde Engineering delivers LNG and LCNG refuelling stations supplying both liquid and compressed natural gas for vehicles. Liquid natural gas (LNG) is stored in a cryogenic tank and then pumped directly to a dispenser for liquid delivery. Alternatively, it can be pressurised and vaporised for delivery as compressed natural gas (CNG).

Big Break Through For Small Scale LNG

Big Break Through For Small Scale LNG LNG refueling stations are now appearing on the EU major trunk lines. the advent of shale gas has spurred a number of SSLNG liquefaction plants and

Wärtsilä BOG Reliquefaction Wärtsilä LNG Solutions

Our boil off gas (BOG) reliquefaction plants have been installed on numerous vessels, including the entire Q Flex fleet of m 3 LNG carriers. The 31 Wärtsilä LNG BOG reliquefaction plants delivered to the Q Flex fleet are installed on ships driven by slow speed diesel propulsion engines.

LNG Terminals, Marine Systems, L CNG Stations, Peak

Liquefied natural gas (LNG) and compressed natural gas (CNG) are increasingly becoming a normal fuel for vehicles to not only reduce emissions, but reduce fuel cost. An important piece of infrastructure needed to excel this movement is an LCNG fueling station. An LCNG station is a combination LNG and CNG station that uses LNG supplied by tanker

Small Scale Liquefied Natural Gas (LNG) Market 2015 2025

In China such plants are also used to provide fuel for heavy vehicles at industrial sites such as coal mining trucks. Satellite stations complement the whole LNG supply chain.

MINIMIZING THE CO2 EMISSION FROM THE LIQUEFACTION

In the LNG power chain, which includes upstream, liquefaction, LNG tanker, receiving terminal and power generation elements, efforts have been made to reduce the CO2 emissions caused by each element. Among these elements, the liquefaction plant process has great potential to reduce the CO2 emissions, by way of:

LNG Liquified Natural Gas , the cleaner alternative fuel

EVOL LNG provides liquefied natural gas as a fuel for remote power stations, industrial facilities, marine bunkering and transportation that’s cleaner than diesel and LPG. We help our customers make an effortless transition to the fuel of the future.

LNG Vehicle Fueling Chart Industries

Fueling Stations & Vehicle Fueling. Chart vehicle fueling stations are dedicated to safely and reliably delivering fuel for all natural gas vehicles (NGV) and fleets. LNG, including liquid biogas (LBG), is typically used for heavy duty vehicles such as trucks, buses and special handling vehicles, and CNG for passenger cars and vans.

HAM opens its first Gas Station CNG LNG in Asturias

The new service station opened by HAM makes available to all users a liquefied natural gas (LNG) pump for trucks and double compressed natural gas (CNG) pump for trucks and light vehicles. The innovative dual fuel system of CNG allows refueling two CNG vehicles in a single pump.

Pioneer LNG Liquefied Natural Gas Provider for

Delivering the liquid fuel of the future today. Providing Energy Independence to American in Touch Welcome to Pioneer LNG The principles of Pioneer LNG bring a combined 65 plus years in all facets of the energy business. We have hands on experience in the distillate, natural gas, propane and power. We are now focusing [ ]

LNG plants mini and small scale liquefaction technology

This enables very competitive capital and operational costs for LNG plants with capacities of up to 300,000 TPA. BIOGAS LIQUEFACTION. Biogas is a renewable source of energy, and thus liquid biogas (LBG) can be characterised as a renewable fuel.

Small and medium scale LNG terminals

dual fuel power plant and include fuel storage and LNG processing systems in the size range of 100 20,000 m3. The storage is mainly built as bullet tanks and the capacity depends on the size and operational profile of the power plant and the frequency of filling. For example, a 50 MW base load plant with an average of 12 days

FLNG Technology LoneStar LNG

FLNG TECHNOLOGY. LIQUEFACTION VESSEL CONVERSION. The liquefaction vessel is based on a standard Moss type LNG carrier of 155 170,000 m3 capacity and equipped with Dual Fuel Diesel Electric (DFDE) propulsion. The Moss containment system eliminates risk of damage from sloshing in slack tanks during filling.

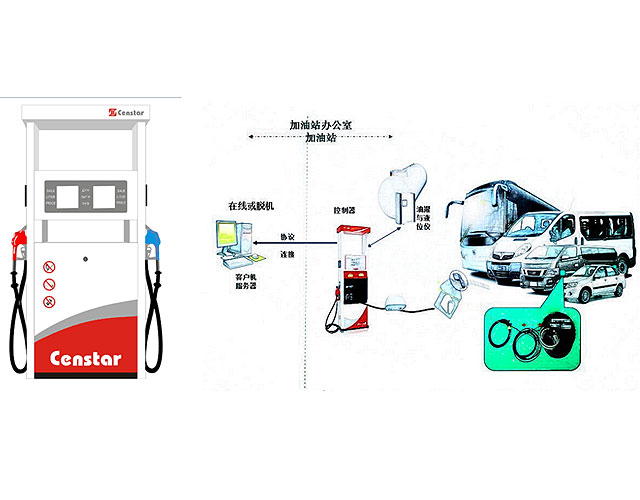

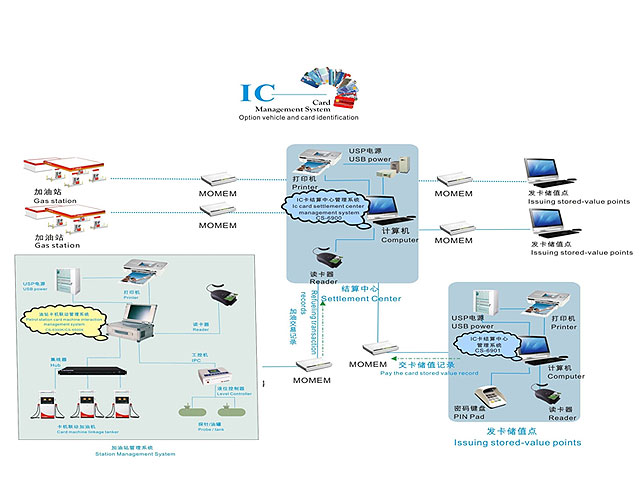

LNG/LCNG Fueling Station Censtar

Short animation show how a Chart LNG and LCNG Fueling station operates. Skip navigation LNG/LCNG Fueling Station Chart Industries How GE's Small Scale Liquefied Natural Gas (LNG) Plant

Shell ships long awaited first LNG cargo from Australia's

Prelude will produce 3.6 million tonnes a year of LNG, 1.3 million tonnes a year of condensate and 400,000 tonnes a year of liquefied petroleum gas (LPG).

World's LNG Liquefaction Plants and Regasification Terminals

World's LNG Liquefaction Plants and Regasification Terminals Global LNG info provides a wide range of perfect information and solutions for its clients in accordance with their required information by offering the most compatible and cost effective services for them.

Liquefied Natural Gas (LNG) Plants for Sale IPP

The natural gas fed into the LNG plant will be treated to remove water, hydrogen sulfide, carbon dioxide and other components that will freeze (e.g., benzene) under the low temperatures needed for storage or be destructive to the liquefaction facility. LNG typically contains more than 90 percent methane.

LNG INEEL Bus Liquefied Natural GasKryopak liquefied

Their design for the refueling station uses the physical properties of the liquefied fuel to provide the force needed to transfer the LNG from the tank of the station to the tank of the vehicle, and reduces the cost to $100,000 or less, competitive with gasoline stations. Liquefied

LNG Fueling Stations Locations, Maps and More

Are we missing a LNG Fueling Stations location or another place that you know about? Click here to add a place to the map and help make MapMuse even better! Directory and Interactive Maps of LNG Fueling Stations across the Nation including address, hours, phone numbers, and website.

Small Scale Liquefied Natural Gas (LNG) Market 2015 2025

Visiongain identifies LNG import terminals and liquefaction plants as small scale if their regasification or liquefaction capacity is less than 1 mtpa. Other elements of the small scale LNG market

How Does LNG Work? Rigzone

Liquefaction. This temperature drop liquefies the methane present in the natural gas, making transportation at atmospheric pressure in the form of LNG possible. LNG is mainly constituted of methane and generally contains ethane, as well. Liquefied Petroleum Gas (LPG) may also be present in the LNG.

LNG facilities scheme : LNG : CRYOGAS M&T POLAND

LNG is transported from the liquefaction plant to the regasification stations in specialized cryogenic tankers, where the low temperature of liquefied gas is maintained during transport. A typical tanker has a capacity of 18 tons, which after regasification produces 25,600 m³ of fuel in gas form.

LNG and natural gas processing plants Linde Engineering

Liquefied Natural Gas (LNG) LNG is natural gas in its liquid form. In order to liquefy natural gas, it must be cooled to cryogenic temperatures of approximately 160°C. As a liquid, natural gas occupies only 1/600 of the volume of natural gas (at atmospheric pressure) in its gaseous form and therefore allows for more economic and practical storage.

HAM Group Liquefied natural gas service stations LNG

The service stations of liquefied natural gas LNG are fully automated, allow a fully autonomous operation that can be monitored in real time from anywhere. The supply of fuel in all General de Gasolineras Stations includes the LPG option in addition to the already known Diesel A (with and without additives) and B, and Unleaded petrol 95 and 98. You can also manage it on LNG purchase (liquefied natural gas).

Critics say lifeline for Massachusetts LNG power plant

The plant buys most of its fuel from an adjacent import terminal known as Distrigas. If Mystic closed, Distrigas would lose a major customer and be in danger of going out of business as well. In the event of a winter cold snap, natural gas would be needed for heating, and the region’s gas burning power plants could be left short of fuel.

Case Study Liquefied Natural Gas

diesel fuel is represented by the orange bar atop the LNG bar. Total fuel use was approximately 407,000 diesel equivalent gallons (DGE) of LNG and 20,000 gallons of diesel for the LNG trucks over the 15 month data collection period. The leet reported only LNG fuel use, so the 5% diesel fuel was added to the total fuel use as a calculation.

Introduction to Liquefied Natural Gas DTN

Overview of the LNG industry (global gas facts, LNG market, history, full cycle case study). LNG value chain (gas field, liquefaction plant/train, shipping, regas terminals). Technology developments (cryogenic materials, heat exchangers, environmental and safety issues).

Liquefied natural gas Wikipedia

The most important infrastructure needed for LNG production and transportation is an LNG plant consisting of one or more LNG trains, each of which is an independent unit for gas liquefaction. The largest LNG train in operation is in Qatar, with a total production capacity

Small Scale Liquefied Natural Gas (LNG) Market 2015 2025

Other elements of the small scale LNG market are bunkering facilities used by LNG fuelled vessels, infrastructure to supply LNG as a fuel for road vehicles and LNG satellite stations

LNG Liquefaction & Re gasification Systems VALMAX

LNG Liquefaction system is a process of LNG Train, which is a process of re liquefying the gas that has gone through BOG or Gas Treating Process. Skip to content +82 31 478 4020~3 #10, Asan Techno Valley st 387, Dunpo myeon, Asan si, Chungcheongnam do, Korea

LNG fuelling stations Linde Engineering

LNG fuelling stations Linde Engineering delivers LNG and LCNG refuelling stations supplying both liquid and compressed natural gas for vehicles. Designed and built by Cryostar, a member of the Linde Engineering Division, our LNG and LCNG refuelling stations deliver natural gas for refuelling vehicles, either in liquid or gaseous form, or combined.

Equipment and Solutions MARINE LNG FUELLING AND

Small Scale Liquefaction Satelite LNG Plant Truck Stop LNG refuelling station LNG Feeder LNG Floating Storage and Regasi˜cation Unit LNG Trailer LNG Carrier Ferry LNG Bunkering Barge LNG Receiving Terminal City Fleet LNG Station Small Town Land˜ll Digester Gas Pipeline Peak Shaving Plant CSM CBM LCNG / LNG Station Small Scale Liquefaction

Distributed LNG Production Galileo Technologies

The Cryobox LNG Production Station is a fuel producing unit that offers approximately 15 metric tons per day of LNG. Portability / plug and play Every Cryobox module has the size of a 40 feet sea container, which facilitates its delivery in a single trailer and multiple relocations in reduced footprint plant areas.

2019 Mini LNG Liquefaction Plant, LNG CNG Transportation

Mini LNG Liquefaction Plant Factory,LNG CNG Transportation Trailer and Container Suppliers,CNG Compressor and Refilling Station Manufacturers,China High quality Mini LNG Liquefaction Plant Company,Sales LNG CNG Transportation Trailer and Container Manufacturers.

LNG for transport Shell Global

LNG for transport. A range of vehicles and fuels, including liquefied natural gas (LNG), will be needed to meet increasing demand for transport as the world seeks to tackle emissions. Shell believes that natural gas could form a bigger part of the transport energy mix as a lower carbon fuel, alongside developments in vehicle efficiency, biofuels,

All electric LNG plants Better, safer, more reliable and

ABB paper All electric LNG plants 3 For LNG plants, except in rare cases, electric energy is not available from a nearby power station or reliable public grid. However, it can be produced in the plant itself by utilizing large commercial power generation gas turbines in the 100+ MW range. In a combined cycle power plant, the fuel to electric

LNG liquefaction plants Cryonorm

LNG liquefaction plants. Liquefaction of gases is physical conversion of a gas into a liquid state ( condensation ). Main reason for such is to reduce its volume in order to transport in liquid state to customers site. Cryonorm provides worldwide Natural Gas Liquefaction Plants in

Capabilities in LNG for fuel BOC Australia A Member of

This includes construction of the plant, the liquefaction process, storage of the gas in its liquefied form, to distribution and refuelling stations. This end to end process comes full circle as BOC works closely with its customers to work out future demand for production plants and sites for refuelling stations.

Bohlen & Doyen LNG filling stations Liquefied natural

LNG filling stations (liquefied natural gas filling stations) Besides the well known CNG, liquefied natural gas (LNG) has been moving more and more into focus during the past few years. By cooling it down to 164 to 161 °C natural gas is liquefied and then has only 1/600 of the volume of CNG in gaseous form.

Liquefaction for LNG Projects

A number of liquefaction technologies are available for use in LNG projects worldwide: Currently, three LNG projects are proposing to utilize OSMR® technology: Magnolia LNG Project, in Lake Charles, Louisiana, USA; Gladstone LNG Project ‐ Fisherman’s Landing, in Gladstone, Queensland, Australia.

Aeroderivative Gas Turbines for LNG Liquefaction Plants

today. After this installation, all LNG plants have used gas turbines ranging from Frame 5Ds, Frame 7EA, Frame 6B and recently, the Frame 9E3. The world’s first aeroderivative driven LNG liquefaction plant at Darwin LNG was started up in 2006. 3 There is one exception of a recent all electric plant

Message

Message tel

tel Inquiry

Inquiry