Process Design Basics for Stations Facility

Electrical system design refers to the process flow diagram and utility flow diagrams, existing data of flow diagram contain of equipments that’s requires electrical energy (in Horse Power. Hence can be determine electrical equipment sizing, calculation, single line diagram, specification, datasheet.

Mallnow Natural Gas Compressor Station Climate friendly

The Mallnow natural gas compressor station Is one of WINGAS TRANSPORT’S largest compressor hubs. Transports volumes of gas that make up around a third of Germany’s natural gas requirements. Uses the waste heat of the gas turbines to drive an additional steam turbine.

Compressor station Wikipedia

A compressor station is a facility which helps the transportation process of natural gas from one location to another. Natural gas, while being transported through a gas pipeline, needs to be constantly pressurized at intervals of 40 to 100 miles. Siting is dependent on terrain, and the number of gas

Mallnow Natural Gas Compressor Station Climate friendly

Mallnow Natural Gas Compressor Station 3 Compressor stations are critically important to the transportation of natural gas. The natural gas covers a distance of several thousand kilometres en route to the final customer. Pressure losses arise in the pipe lines, and these are equalized by compressors sited roughly every 200 km.

Compressor Stations Engineering Entech Engineering, Inc.

Compressor Stations stations; designed to optimize flow. Natural gas compression is a critical component of any natural gas network. Whether your application is upstream at the well pad, midstream at your process facility, a prime mover in your transmission system, or a fuel gas booster for your power plant, compression is what moves your product.

How Does the Natural Gas Delivery System Work? American

Most compressors in the natural gas delivery system use a small amount of natural gas from their own lines as fuel. Some natural gas gathering systems include a processing facility, which performs such functions as removing impurities like water, carbon dioxide or sulfur that might corrode a pipeline, or inert gases, such as helium, that would reduce the energy value of the gas.

Columbia Gas Transmission, LLC Walgrove Compressor

Walgrove Compressor Station is a natural gas transmission facility covered by Standard Industrial Classification (SIC) Code 4922. The station has the potential to operate twenty four (24) hours per day, seven (7) days per week, fifty two (52) weeks per year. The station consists one (1)of 880 hp, 2SLB reciprocating engine and one

Process Gas Centrifugal Compressors Ingersoll Rand Air

making previously unmarketable natural gas reservoirs profitable. Ingersoll Rand has extensive experience in this process. Our custom compressors are designed to meet the varying processes and parameters involved in natural gas liquefaction. Feed Gas Compressor Compresses natural gas received at the plant to the required

Compressing costs CB&I

a station with many parallel compressor trains or a station with just one compressor train; thus allowing the investigation of using multiple trains for varying conditions. For the transmission of 100% of the design flow of gas, all the compressor stations must be operational.

SCADA and Telemetry in Natural Gas Operations ASGMT

Natural Gas pipeline you typically find compressor stations, valve stations and meter stations. Larger facilities such as gas storage, gas processing and fractionators in midstream can also be considered station. Basically stations are remote facilities whose operation impacts the operation of the pipeline. Compressor Stations Each compressor typically has its own “Unit PLC”,

The Interstate Natural Gas Transmission System: Scale

Pipeline quality natural gas is an odorless transparent gas, consisting primarily of methane (CH 4), with minor amounts of ethane, propane, butane, hydrogen sulfide, carbon dioxide, nitrogen, and oxygen. The first step downstream of production areas in the natural gas transmission process is separating the various liquids and gases from each other.

Gas Compressor Diagram Wiring Source

Gas Compressor Diagram. welcome to my blog here I will show you a little more what you are looking for Gas Compressor Diagram below there are some photos and a little about Gas Compressor Diagram that you can see and read, hopefully in accordance with what you are looking for.

Compressor Stations Tennessee Gas Pipeline

attached diagram.) 1. Station Yard Piping Natural gas enters and exits the compressor station through station yard piping. Gas enters the station at the suction header. From there, gas passes through the scrubbers, which remove any solids and most liquids from the gas. Because the temperature of natural gas rises when it is compressed, high pressure gas coolers may be used to

Natural gas compression plant schematic Mobil™

Natural gas compression plant Explore equipment and application specific to your industry in the below schematic. You can click on red hotspots in the schematic or on items in the right hand equipment menu to see corresponding lubricant information.

Typical PFD for Centrifugal Compressor Systems

Compressor surge occurs due to high back pressure on the compressor discharge so that very small gas flow can be pushed through. This is indicated by a surge line on any compressor map . To avoid compressor surge the back pressure at compressor has to be lowered so that more gas flow can be circulated through the compressors.

Natural Gas Liquids Recovery.

may provide for a higher sales value than the pipeline gas by itself. Figure 1 shows a block flow diagram for a typical natural gas processing scheme, and indicates where CRYO PLUS™ is integrated within the operation. CRYO PLUS™ Benefits The optimum C 2 and C 3

Landon Carroll R. Weston Hudkins University of Oklahoma

just over $220 worth of natural gas wasted in fuel costs per year per compressor station. Another assumption is that the pipe and compressor are running 350 days a year.

Natural Gas Liquids Recovery.

shows a block flow diagram for a typical natural gas processing scheme, and To avoid ice and hydrate formation in the cryogenic section of the process, the water content of the gas is reduced to an acceptable level through vapor flows to the inlet of the expander/compressor. As the gas expands, it provides the work/energy for the

Example Kansas Regular Class I Application for a Natural

Since the processes involved in the operation of compressor stations are understood by the department, it is not necessary to include a GI 02A Process Flow Diagram or a GI 06 Stack/Vent Diagram in a natural gas compressor station Class I application. Under GI 09 Determination of Applicable Requirements, the K.A.R. opacity reference citation in item

Types of Gas Compressors Piping engineering

A gas compressor is a mechanical device that increases the pressure of a gas by reducing its volume. Compressors are prime movers of gas and air in process industries. They are used to increase static pressure of the gas and deliver it at specified pressure and flow rate in a process application. Use of compressed gas can be found in numerous applications.

Natural Gas Compressor Station Process Flow Diagram Buy

Natural Gas Compressor Station Process Flow Diagram , Find Complete Details about Natural Gas Compressor Station Process Flow Diagram,Natural Gas Compressor Diagram,Natural Gas Compressor Manufacturers,Natural Gas Compressor Station Process Flow Diagram from Supplier or Manufacturer Henan Yuanju Machinery Equipment Co., Ltd.

Compressor station Wikipedia

Compressor station. A compressor station is a facility which helps the transportation process of natural gas from one location to another. Natural gas, while being transported through a gas pipeline, needs to be constantly pressurized at intervals of 40 to 100 miles. Siting is dependent on terrain, and the number of gas wells in the vicinity.

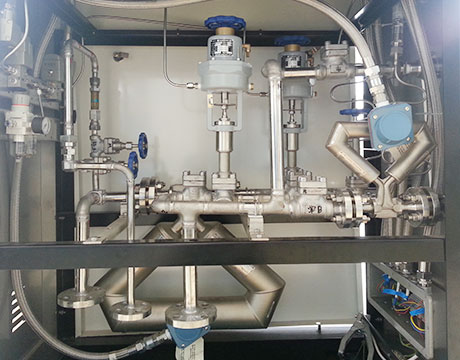

Gas Compressor Package Censtar

We have delivered gas compressor packages for power plants up to 200 MW (based on 2 up to 4 gas turbines). The "typical" gas compressor range of Eltacon: gas inlet between 1

(PDF) HANDBOOK OF NATURAL GAS TRANSMISSION AND

HANDBOOK OF NATURAL GAS TRANSMISSION AND PROCESSING. 2006. Wagner Soriano. Download with Google Download with Facebook or download with email. HANDBOOK OF NATURAL GAS TRANSMISSION AND PROCESSING. Download. HANDBOOK OF NATURAL GAS TRANSMISSION AND PROCESSING.

Natural gas compression ScienceDirect

As the piston reverses its travel, the gas remaining within the cylinder expands (from point 4 to point 1) until it equals suction pressure and the piston is again in position A. Natural Gas Compression of a volute, which can further convert velocity into static pressure, or a simple cavity that collects the gas before it exits the compressor through the discharge flange.

Natural Gas Compressor Stations Explained Hanging H

There are basically three stages for a natural gas compressor station: scrubbing, compressing, and cooling. The natural gas compressor station layout is fairly straightforward, as the gas compressor stations process is a continuous flow process. Here is a natural gas compressor station process flow diagram, courtesy of Spectra Energy. This diagram explains the process flow.

Natural Gas Pipelines Energy Explained, Your Guide To

Compressor stations (or pumping stations) on the pipeline network keep the natural gas flowing forward through the pipeline system. Local distribution companies deliver natural gas to consumers through about 1.5 million miles of small diameter, lower pressure service lines.

Compressor Stations—an essential part of a natural gas

What is the purpose of a compressor station? Maintains the pressure of natural gas as it flows through a pipeline. Why are compressor stations needed? Natural gas loses pressure and may pick up contamination in the pipeline. The compressor stations increase pressure and can include technology to remove liquid and particle contamination picked up in transit. Compressor stations are located at

Natural Gas Compressor Stations on the Interstate Pipeline

more than 1,200 natural gas compressor stations to maintain the continuous flow of natural gas between supply area and consumers (Figure 1). Compressor stations are “pumping” facilities that advance the flow of natural gas. They are usually situated between 50 and 100 miles apart along the

The basics of a compressor station

Station Natural Gas Scrubber. As gas enters the compressor station from the pipeline, it passes through a natural gas scrubber vessel. This vessel is designed to remove free liquids, dirt or other particulates from the gas stream before it enters the compressors.

Reciprocating compressor PetroWiki

Fig. 13—Compressor process flow diagram with integral (pulsation vessel) separator (courtesy of Dresser Rand). Recycle valve Compressor suction pressure decreases as the flow rate decreases until the gas expands to satisfy the flow required by the cylinder.

Natural Gas Compressor Station Baumgarten Censtar

The largest import and entry station for natural gas in Austria is located in Baumgarten (Lower Austria). Natural gas from Russia, Norway, and other countries is

Compressor Station System Diagram

Compressor Station. As the produced fluids flow from the formation through the wellhead, pipelines transport the liquids and gases to the various separation, cleaning and storage facilities; and then, ultimately transport the processed products to their destinations.

Ingersoll Rand Natural Gas Compressor Parts

We have Ingersoll Rand Natural Gas Compressor parts in stock and ready to ship. We accept Visa and MasterCard Payments for quick delivery. Make sure you buy Genuine Ingersoll Rand CNG compressor replacement parts. These parts are specifically designed for natural gas duty. They not only last longer, but will save you money. All Genuine Ingersoll Rand parts are shipped in an IR box with a hologram

Process flow diagram Typical oil refinery Natural gas

Process flow diagram Typical oil refinery. This is a schematic process flow diagram of the processes used in a typical oil refinery. This process flow diagram (PFD) example was redesigned from the Wikimedia Commons file: . This file is licensed under the Creative Commons Attribution Share Alike 3.0 Unported license.

GOFF CONNECTOR LLC G35 D GENERAL PERMIT

G35 D GENERAL PERMIT REGISTRATION APPLICATION Connector Compressor Station Harrison County, West Virginia February, 2018 install a natural gas compressor station. The compressor station will include: three (3) Caterpillar G3606 compressor ☒ Process Flow Diagram Attachment D ☒ Process Description Attachment E

Appendix C Process Flow Diagrams

Tail Gas + Natural Gas . Furnace Fried at 30% Full Load . To Atmosphere . Steam/Air Mixture . Effluent sent to combustion chamber (i.e. Firebox) Notes: 1. Max decoking firing time for all six furnaces is 864 hours per year @ 30% normal load (119 MMBtu/hr) 2. Decoking operations will occur a maximum of 12 events per year per furnace.

Oil and Gas Pipeline Construction: Step By Step Visual Guide

Pipeline Construction: Step by Step Guide The current natural gas pipeline boom gives many homeowners a first row seat to the process of pipeline construction. The rush to move natural gas to markets places pipelines too close to homes, with construction taking place in backyards, farms, pastures, and right at the mailboxes of residents

Natural Gas Industry Process Flow Diagram SmartDraw

Natural Gas Industry Process Flow Diagram. Create Process Flow Diagram examples like this template called Natural Gas Industry Process Flow Diagram that you can easily edit

Natural gas processing Wikipedia

Description of a natural gas processing plant. There are a great many ways in which to configure the various unit processes used in the processing of raw natural gas. The block flow diagram below is a generalized, typical configuration for the processing of raw natural gas from non associated gas wells. It shows how raw natural gas is processed into sales gas pipelined to the end user markets.

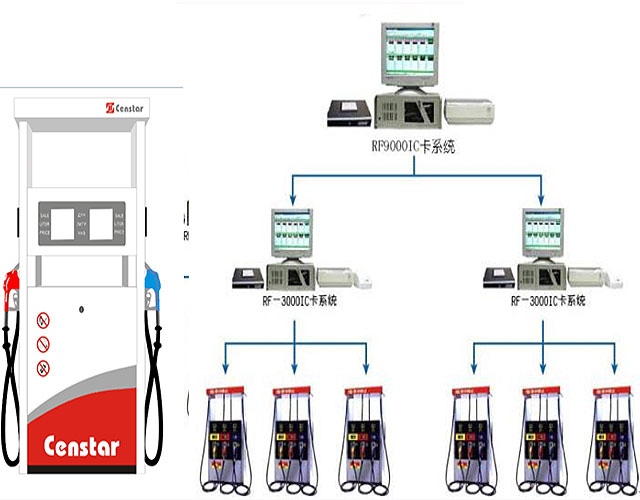

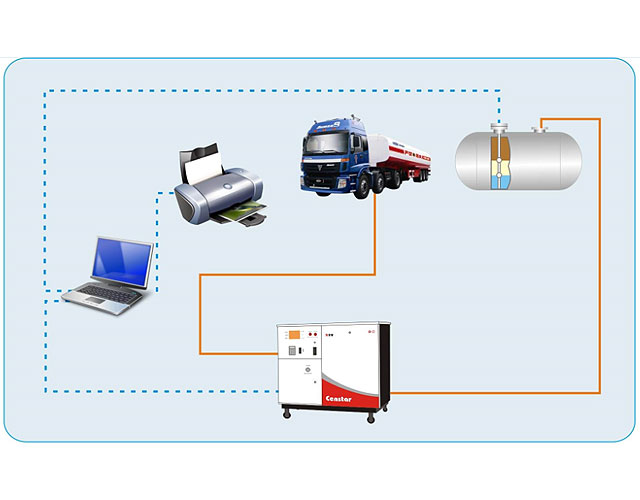

Compressed Natural Gas (CNG) Filling Stations Honeywell

Honeywell's Gas Filling Stations offer solutions including control stations for compressed natural gas (CNG), fuels and the growing biogas market. The station technology is available in two series that differ by the supply and nominated capacity.

Docket No. CP80 (DESIGN MANUAL) Exhibit Z 9.2 Stations

2.1.8 Process The process flow diagram of the station main gas piping is shown on Figure . This includes the launcher and r eceiver, liquid vapor separators (scrubbers), pipeline compress or, chillers, gas heaters and blow down dr um with flare stack. The nor mal sucti on pressure at t

Docket No. CP80 (DESIGN MANUAL) Exhibit Z 9.2 Stations

Process Flow Diagram, Station Mainline Gas Piping. Electrical One Line Diagram, Compressor Station . Process Flow Diagram, Direct Refrigeration Unit. Gas Metering Station, Prudhoe Bay, Overall Plot Plan . Gas Metering Station, Yukon, Overall Segment of the Alaska Natural Gas

Compressor Stations: What They Do, How They Work, and Why

Compressor stations enable the natural gas itself to travel through the pipelines which is crucial to the natural gas transport system. They also allow the gas to be rerouted into storage areas during periods of low demand.

Message

Message tel

tel Inquiry

Inquiry