Dehydration with glycol PetroWiki

The main use of EG in the dehydration of natural gas is in depressing the hydrate temperature in refrigeration units. Of the other three glycols, triethylene glycol (TEG) is the most commonly used glycol for dehydration of natural gas because of the advantages relative to diethylene glycol (DEG):

High Pressure Gas Dryer Unit,natural gas dryer,CNG station

Natural gas dryers remove water vapor prior to storing or using natural gas for a vehicle fuel. High water content can cause blockage of CNG in fueling systems and can contribute to corrosion in storage vessels and dryer is an ideal system for drying small volumes of natural gas for stations with intermittent use.

Compressed natural gas filling stations

gas dehydration in a dehydration unit; storage in batteries at the pressure of 25 MPa and distribution through gas dispensers at the pressure of 20 MPa. A network of CNG filling stations is formed on the basis of standard vehicle series. More than 200 CNG filling stations were operational in Russia by the beginning of 2000.

LNG Dehydration(Drying of Natural Gas) CHERIC

LNG Dehydration(Drying of Natural Gas) Absorption and refrigeration with hydrate inhibition is the most common dehydration process used to meet pipeline sales specifications.

Glycol Dehydrator Exterran

Glycol Dehydrators, part of natural gas dehydration systems, remove water vapor from gas streams to prevent the formulation of hydrates and corrosion in pipelines. The Glycol Dehydration Unit is a reliable, efficient system for removing water from natural gas well streams in order to meet typical pipeline and process specifications.

Natural Gas Dehydration US EPA

Produced gas is saturated with water, which must be removed for gas transmission Glycol dehydrators are the most common equipment to remove water from gas 36,000 dehydration units in natural gas production, gathering, and boosting Most use triethylene glycol (TEG) Glycol dehydrators create emissions Methane, Volatile Organic Compounds

High Pressure Gas Dryer Unit,natural gas dryer,CNG station

Natural gas dryers remove water vapor prior to storing or using natural gas for a vehicle fuel. High water content can cause blockage of CNG in fueling systems and can contribute to corrosion in storage vessels and dryer is an ideal system for drying small volumes of

Dehydration of Natural Gas, water in CNG CNG fueling

This water vapor must be removed from the gas stream in order to prevent the formation of solid ice like crystals called hydrates. Hydrates can block pipelines, valves and other process equipment. The dehydration of natural gas must begin at the source of the gas in order to protect the transmission system.

ENGINEERING DESIGN GUIDELINES GAS DEHYDRATION

systems. Natural Gas in transit to market should be dehydrated to a controlled water content to avoid hydrates, as well to minimize the corrosion problems. Dehydration of Natural Gas is the removal of the water that is associated with natural gases in vapor form. The natural gas industry has recognized that dehydration is

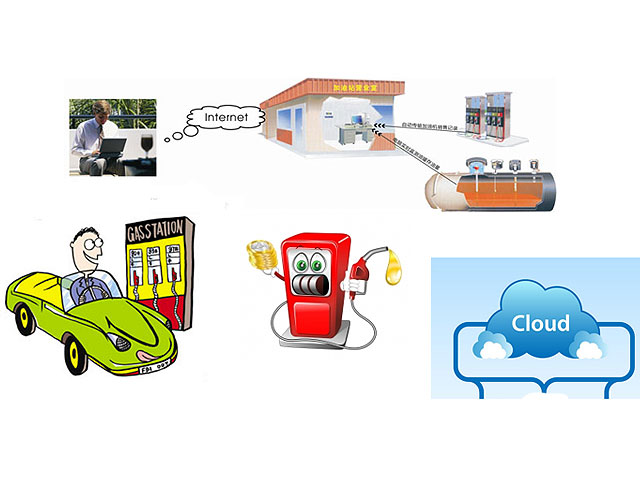

CNG Filling Stations Products Compex

Natural gas from a pipeline is cleaned from mechanical impurities by filter system and then goes to a compressor, where it's compressed. After condensed moisture has been separated in a dehydration unit, gas is pumped into refillable gas storage under the pressure of 20 25 MP. Treated gas is used for fuel vehicles using CNG dispensers.

Natural Gas Cng Dehydration Unit For Gas Filling Station

Natural Gas Cng Dehydration Unit For Gas Filling Station , Find Complete Details about Natural Gas Cng Dehydration Unit For Gas Filling Station,Gas Dehydration Unit,Natural Gas Dehydration Unit,Natural Gas Cng Dehydration Unit For Gas Filling Station from Dehumidifier Supplier or Manufacturer Sichuan New Tianyuan Technologies Co., Ltd.

Natural Gas Dehydration and Conditioning for NGV Refueling

Xebec Adsorption has been supplying Natural Gas Dryers for CNG (Compressed Natural Gas) fueling stations worldwide for over twenty five (25) years. It has been only in recent years, however, that more and more countries have been turning to natural gas as an alternative fuel source for transportation.

Update and Operation of Natural Gas Compressor Stations

engine driven air compressors, boilers, line heaters, tanks, glycol dehydration units, flares, or other specified control devices. All natural gas compressor stations with glycol dehydration units, flares, or other specified control devices herein designed and operated for the purpose of gathering, transmitting,

Natural Gas: Natural Gas Dehydration Unit For CNG

Is especially used for deep dehydration of natural gas in CNG gas filling station The general technical parameters that can be meet by the deep dehydration device of natural gas Low pressure front, ultra low pressure front, large water content, super flow, high pressure postposition etc. 2. Equipment design working pressure range 3.

The Glycol Dehydration Process: A Basic Overview Oil and

Triethylene glycol (TEG) is the most common type of hydroscopic liquid used in natural gas dehydration. In short, TEG is like a liquid sponge that only attracts water or water based solutions. Triethylene glycol (TEG) is used because it has a high boiling point and low freeze point; making it

China CNG Compressor,Natural Gas Compressor,Dispenser

Chengdu Tianyi Natural Gas Compressor Manufacturing Co.,Ltd. has been actively involved in the Natural Gas Industry since 2000,which is a professional CNG equipment manufacturer and technical service company in on many years of experience in CNG Station solution,Tianyi is capable of supplying CNG refueling station equipments, CNG

Natural Gas Dehydration Unit Dehydration of Natural Gas

Membrane Dehydration. In GENERON ® membrane gas dehydration systems, the feed gas is filtered to remove any trapped liquids and aerosols. The gas then enters the GENERON ® membrane filters, where the H 2 O, CO 2 and H 2 S permeate through the membrane. The non permeated gas, mainly CH 4, remains at process pressure and becomes the product gas.. Membrane Dehydration

CNG Mother Station Compressor

A mother station will always be located near a natural gas pipeline. Mobile storage allows transportation of natural gas to a site that does not have access to a natural gas pipeline.Typical applications where mother stations are used are to supply gas to: daughter CNG stations, industries and city gas distribution systems.

Home Filling Station CNG Conversion Kit Supply

After some basic math you can calculate the amount of natural gas you would need to compress for a full tank. In Utah, for example, Questar Gas currently charges about 82

ENGINEERING DESIGN GUIDELINES GAS DEHYDRATION

Natural Gas either from natural production or storage reservoirs contain water, which may condense and may also form solid gas hydrates to block pipeline flow and control systems. Natural Gas in transit to market should be dehydrated to a controlled water content to avoid hydrates, as well to minimize the corrosion problems.

Natural Gas Dehydration_Jereh Oil & Gas Engineering

Natural Gas Dehydration. Molecular Sieve Dehydration Single unit processing capacity can reach 2,240×104 Nm 3 /d. High dehydration accuracy; 0.1 ppm water in purified gas is available. TEG Dehydration Strong device applicability with wide range of dew point decrease. Scale of single unit: 980×104 Nm 3 /d.

Alternative Fuels Data Center: Natural Gas Fueling Station

Natural Gas Fueling Station Locations. Find compressed natural gas (CNG) and liquefied natural gas (LNG) fueling stations in the United States and Canada. For Canadian stations in French, see Natural Resources Canada.

NATURAL GAS DEHYDRATION WITH TRIETHYLENE

This work studies the dehydration of natural gas using Triethylene Glycol (TEG)” as the dehydrating agent or absorbent to examine the water content of the natural gas stream when the dehydrating agent and the gas flows in counter current manner in an absorption column and to determine hydrate formation temperature and prevent its occurrence.

Dehydration of Natural Gas, water in CNG CNG fueling

This statement, now known as Dalton’s Law of Partial Pressures, allows us to compute the maximum volume of water vapor that natural gas can hold for a given temperature and pressure. The wet inlet gas temperature and supply pressures are the most important factors in the accurate design of a gas dehydration system.

Natural Gas Dehydrators & Dryers

Natural Gas Dehydration The purpose of natural gas dehydration units (also called natural gas dehydrators) is to remove water from natural gas and natural gas liquids. When produced from a reservoir, natural gas usually contains a large amount of water and is typically completely saturated or at the water dew point.

Small CNG Station Designed for the Smaller Business

Small Natural Gas Compressor Station Design Small Natural Gas Compressor station designed for small smart fleets. This small CNG Station has only 2 connections (Inlet gas connection and 460V/3 PH to the motor starter box) and is ready to use for natural gas refueling. This natural gas compressor station is perfect for those with smaller fleets looking for a smaller starting CNG unit.

Natural Gas Dehydration Unit With TEG (Tri Ethylene Glycol

An example of natural gas dehydration, using TEG, was built with ProSimPlus. The interesting points of this example lie in the use of the “absorption” module for the contactor model and in the representation of two columns connected in series (the TEG regenerator and the TEG stripper) by a single ProSimPlus “stripper” module.

Dehydration of Natural Gas Joule Thomson Expansion

Dehydration of Natural Gas. Natural gas enters the unit at the bottom of the adsorber tower and rises through the tower were it intimately contacted with the TEG solution flowing downward across bubble trays. Through this contact, the gas gives up its water vapor to the TEG.

Message

Message tel

tel Inquiry

Inquiry