oto courtesy o S rmy Lubrication Systems

Lubrication customers span . the world’s fleet of aircraft and their engines, including: From industry leading lubrication pumps and accessories to oil reservoirs and pump/ reservoir systems and subsystems designed to meet customer specifications and envelope requirements, Parker Aerospace delivers. Our unique designs consistently save space and

Maritime Applications Lubricant Oil NETZSCH Pumps

Maritime Applications Lubricant Oil; When pumps are used on ships and in ports, the technology must meet special requirements: this means the pumps should not only cope with a really wide variety of fluids, but should also be as space saving, maintenance free and easy to handle as possible. The different geometries of the three pump

Oil pump (internal combustion engine) Wikipedia

The oil pump in an internal combustion engine circulates engine oil under pressure to the rotating bearings, the sliding pistons and the camshaft of the engine. This lubricates the bearings, allows the use of higher capacity fluid bearings and also assists in cooling the engine.. As well as its primary purpose for lubrication, pressurized oil is increasingly used as a hydraulic fluid to power

Automatic lubrication system Wikipedia

An automatic lubrication system (ALS), often referred to as a centralized lubrication system, is a system that delivers controlled amounts of lubricant to multiple locations on a machine while the machine is operating. Even though these systems are usually fully automated, a system that requires a manual pump or button activation is still identified as a centralized lubrication system.

Lubricants & Lubrication Systems TRCI Industrial

Dosing Pumps are pumps with one or or more plungers. When activated by an e.g. solenoid, lubricant is delivered at each outlet.

CHAPTER 5 JET AIRCRAFT ENGINE LUBRICATION SYSTEMS

2. Cooling. Lubricating oil must cool moving parts by carrying heat away from gears and bearings. This is an important function considering the many parts located next to burners or turbine wheels, where temperatures are over 1700 degrees Fahrenheit (F). Liquid lubricants cool by pumping or spraying oil on or around bearings or gears.

How Engine Lubrication Works Briggs & Stratton

Pressure System for Distributing Oil. Pressure lubrication systems provide a controlled flow of clean oil to bearing for less wear and longer engine life. A high efficiency pump in the oil pan supplies lubricant to the crankshaft and connecting rod bearing surfaces. The pressure system incorporates a premium spin on oil filter. Pressure lubrication is used on select single cylinder engines.

API Gear Oil Specifications

Lubricants meeting the requirements of API MT 1 service provide protection against the combination of thermal degradation, component wear, and oil seal deterioration, which is not provided by lubricants in current use meeting only the requirements of API GL 1, 4, or 5.

Lube System Modifications Boost Reliability

Maintain bearing supply pressure within the acceptable range of 14 to 26 psig for all pump combinations. The designed lubrication oil system retrofits were implemented at both SONGS units from 2002 to 2003. Thus far, results have been positive and the system is operating as designed.

Lubrication Certification: Types, Requirements, Benefits

Society of Tribologists and Lubrication Engineers (STLE) Founded in 1944, STLE was originally known as the American Society of Lubrication Engineers. It offers the certifications listed in Table III. Originally designed for lubrication engineers, the CLS is the oldest—and considered the highest level—lubrication certification. The very rigorous CLS exam (which had a 60% pass rate in 2010)

Understanding the Basics of Automatic Lubrication Systems

Some pumps are also meters, such as the piston pumps used in a box lubricator, but most of the time the pump is a separate unit. Controller. A controller runs a schedule or program to dispense lubrication on a regular basis. Some pumps have a built in controller, but many systems use a controller that is separate from the pump.

Best practices for lubing API centrifugal pump bearing

A combination design would incorporate a metallic disc and direct contact. The bearings directly contact the oil and the disc provides additional splash lubrication for cooling. Figure 2: Pump Cross Section Oil Splash/Direct Contact. The basic concept of the oil mist lubrication system is dispersion of an oil aerosol into the bearing housing.

Lubrication Basics RMACES

LUBRICATION •Pressure increase in the contact zone increases the viscosity •Trapped oil in the contact zone becomes a solid •Metal surfaces in the contact zone are “elastically” deformed •EHD friction (traction) from viscous shearing raises the contact zone temperatures •Examples: Rolling element bearings, gears, cams and followers, and

Oil Mist Lubrication System Working Principle Mechanical

The oil mist generators are usually designed for a capacity of 100 to 125 % of the rated requirements of the system. This requirement is usually jointly decided by the purchaser and manufacturer. If the design capacity is more than 125% care should be taken the oil mist lubrication system can meet the minimum operating condition.

trabon lube systems TRABON LUBRICATION

Posts about trabon lube systems written by trabonlubrication. Alemite Lubrication Products have been a leading name in the lubrication system and equipments industry, with these products being highly sought after products for a wide range of applications.

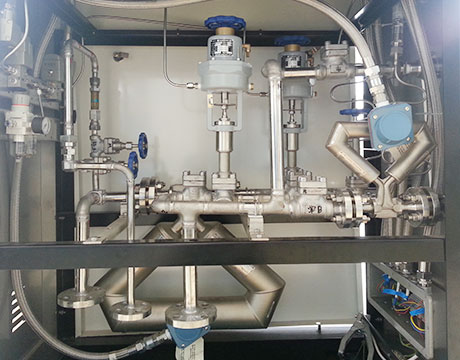

Pressure Lubrication Systems Products & Suppliers

Description: Oil Rite manufactures Lubrication Systems specifically to customer requirements. All systems are engineered, designed, manufactured and fully tested at Oil Rite. This is an example of a custom built Circulating Oil System. This Circulating Oil System has a pump Features: Adjustable Volume; Feed Type: Circulating Oil

Guidelines for Selection of Pump Bearing Lubrication

The lubrication method best suited for bearings in general rotating equipment applications should. be based on the type, size of bearing, shaft speed, load on the bearing, available infrastructure, maintenance accessibility, and life cycle cost considerations.

DESIGNING AUTOMOTIVE ENGINE LUBRICATING SYSTEMS

factors to be considered in the lubrication system design process are flow balancing and pump sizing (volumetric flow rate of oil) required for satisfactory operation. Items such as hydraulic lash adjusters and chain tensioners also require a minimum oil pressure at low engine speeds for adequate operation, which can have a significant affect on the oil pump size.

Lubrication of Gears KHK Gears

An oil pump is used to spray the lubricant directly on the contact area of the gears. Oil Mist Method Lubricant is mixed with compressed air to form an oil mist that is sprayed against the contact region of the gears. It is especially suitable for high speed gearing. Oil tank, pump, filter, piping and other devices are needed in the forced

Oil Sampling Tools US Lubricants

Regularly scheduled oil sampling can help identify contaminants, detect abnormal contamination levels, and help you gauge equipment requirements and the general quality of the lubricants used in your lubrication system. These tools are designed to extract from the best diagnostic locations both system and component specific samples that are representative and repeatable.

GUIDELINES FOR THE LUBRICATION OF MEDIUM SPEED

required here is the Fuel / Lubricating Oil Compatibility. • The rocker arm assembly and valve guides in the valve train. 2. THE LUBRICATING OIL 2.1 A User Language The performance and reliability of the engine and its components are of primary importance to the end user. The lubricant must be seen as an integral part of the engine and its systems.

Lubrication Maintenance Planning Pumps & Systems

Along with the equipment’s lubrication requirements, the equipment also has requirements for: Flushing; Varnish removal; Reservoir maintenance; General system upkeep—such as circulating oil, grease and oil mist; Best of class facilities have implemented programs to optimize their lubrication process, which include a checklist of all equipment and its lubrication requirements.

Lubricating Systems Lubrication Systems

Lubricating system is usually designed according to the working condition of different lubrication requirements of industrial equipment and machinery. The lubrication system mainly consists of electric power motor, hydraulic pump, grease or oil reservoir, filter, cooling device, sealing parts, heating device, buffer system, safety device and alarm functions.

WET & DRY SUMP PUMPS Aviaid OIL Systems

design engineered for a broad spectrum of lubrication requirements. Clearances are set to provide consistent & reliable performance in most competition applications with most general specification petroleum based and synthetic based oils. Moderate vacuum levels are attainable with properly configured pumps. It is a modular design offering seven pump segment widths with more than 35

A Basic Guide to Operating and Servicing Pumping Units in

A Basic Guide to Operating and Servicing Pumping Units in Oil & Gas Production Blog Greg Archbald It may come as a surprise, many of the lively oil wells in the world are only slightly producing wells converted to artificial lift systems.

Pumping Systems Oil Dynamics

Oil Dynamics manufacturers a rugged proprietary design that can be tailored to each specific application requirements with a variety of mechanical seal arrangements, drive trains, flexible suction and discharge arrangements, forced feed lubrication systems and complete instrumentation. Twin Screw Pumping

What Is Lubrication System ? Types Of Lubrication System

From the sump the oil is drawn by the pump and applied to various parts of the engine. Excess oil after serving the purpose will gradually return to the sump. There are three varieties in wet sump lubrication system. They are: 1. Splash lubrication system 2. Splash and pressure system and 3. Pressurized lubrication system. 2.1 Splash Lubrication System:

Designed For Various Requirements Of Pumping Lubricants

Designed For Various Requirements Of Pumping Lubricants With Trailer , Find Complete Details about Designed For Various Requirements Of Pumping Lubricants With Trailer,Dispenser With Trailer,Designed For Lubrication Oil,Mobile Fuel Dispenser from Pumps Supplier or Manufacturer Anhui Ruiling Meter Manufacturing Co., Ltd.

Turbine lubrication: Practical guidelines Turbomachinery

compressor and pump lubrication Some compressors operate with gas discharge temperatures exceeding 160 o C, therefore, the lubricating oil must have good oxidation and thermal stability. In some compressors or pumps, lubricant is in contact with moisture (from handled fluid), which requires good demulsibility of lubricant.

Auto Lube Systems LUBRICATION TECHNOLOGIES

Lubrication Technologies offers a wide selection of the services and products needed to implement a reliability centered maintenance program, including: training, oil and lubrication surveys, oil analysis, Lubrication Engineers (LE) oils, greases, transmission fluids and hydraulic fluids, automatic lubrication systems, single point lubricators, grease guns, grease pumps and hose reels

Oils / Greases / Lubricants Products Leybold

Depending on the requirements (resistance to hydrolysis or oxidation, non flammability, DOT compatibility, approvability for food industry, etc.) different vacuum pump oil fractions, greases and pump fluids are available. The vacuum pump oils and lubricants of Leybold are especially designed with regard to the high demands in vacuum technology.

Bearing Lubrication Definition Intro to Pumps

Pump bearings may be lubricated either with grease or oil depending on the bearing arrangement designed by the pump manufacturer and the preferences of the pump operator. Oil Lubrication in Horizontal Centrifugal Pumps. Horizontal centrifugal pump bearings that are oil lubricated may employ either the ring oil method or the oil bath or oil flood method. In the ring oil method of bearing

What is the lubrication system and Different types of

pressure type lubrication system in the lubrication oil is pressurized by using a gear pump; Oil supplied to lubricate various parts of the moving elements in the system. Splash type lubrication system: The splash type lubrication system in this a dipper made up of metal rod attached at the lower end and of the connecting rod used to splash the oil.

Pump Lube TRABON LUBRICATION

PUMP LUBE. The reliability of oil pumps is determined by the way it handles different application conditions and viscosity of oil. If your old pump lube is faulty and you are searching for a perfect replacement, then there are several points that you should consider.

High Pressure Multi Purpose Pumping Solutions

17 & 18 Pump and Motor: An intelligent, electrically driven lubrication gear pump provides a constant oil feed to all critical components within the power end of the high pressure pump. 19 Filter: The lube oil is filtered to 25 microns to offer maximum protection to the bearing and gear surfaces within the power end of the high pressure pump.

LUBRICANT CLASSIFICATION Behran Oil Company

engine oil pump inlet and provide adequate engine oil pressure during the initial stages of operation. Oils without the letter W, intended for use at higher temperatures, are based on the viscosity at 100°C only. These are measured by ASTM D445 ‘Method of Test for Kinematic Viscosity of temperature and Opaque Liquids’.

Wind Turbine Lubrication and Maintenance: Protecting

"Many different parts of the wind turbine need to be lubrication with a range of lubricants greases to gearbox fluids to hydraulic oils." is a fully synthetic oil designed to withstand the

Rotary Vane Pumps PASCAL series Nanostructure Physics

The forced lubrication system, which includes a built in oil vane pump, enables high performance from atmosphere to the 10 4 mbar range. Low backstreaming rate, pumping stability even for light gases are the results of the advanced engineering design of the I series pumps. Low noise level Specific work on both the pump and the motor design has

trabon lube systems TRABON LUBRICATION

In this context, an Alemite grease pump is an indispensable item it is something you must have, to ensure that you keep your machinery running in the same way that Trabon lube systems, Trabon lube, Trabon lubrication and Farval lubrication play their respective roles in this overview of efficiency and productivity.

(PDF) LUBRICATION SYSTEM

Maintaining perfect control of the adhesion characteristics for different lubricants in contact with surfaces (for example: metal, plastic, glass, ceramics, alloys, composites and so forth

Manual Automatic Lubrication System Honeywell Elster

6 Manual Automatic Lubrication System Eng. Rev.0 en. 1 INTRODUCTION. The Instromet Turbine Gas Meter is a state of the art precision instrument, which measures the flow of gases by means of a turbine wheel. As extension to the known lubrication possibilities Instromet has developed an Automatic Lubrication System.

Maximizing Frac Pump Power End Life Weir Group

MAXIMIZING FRAC PUMP POWER END LIFE Oil & Gas 3 Measurement of oil cleanliness ISO 4406:1999 is an international standard that specifies the code for defining the quantity of solid particles in a lubricating oil. Three code numbers indicate the number of particles ≥4 μm, ≥6 μm, and ≥14 μm, respectively, in each milliliter of fluid.

Lubrication Certification: Types, Requirements, Benefits

Lubrication Certification: Types, Requirements, Benefits EP Editorial Staff Janu This article kicks off a year long discussion on certification of lube pros, the means by which you can achieve it and what’s in it for you when you do.

Designing Effective Lube Oil Storage Reliable Process

Key Components of Effective Lube Oil Storage & Design: Lube oils are very safe to store due to their very high flash points (Class IIIB Fluids). But they still need to be stored away from potential heat or fire sources. Many materials are available for storing lubricants. Poly Lube Storage

Lubrication of Gears KHK Gears

An oil pump is used to spray the lubricant directly on the contact area of the gears. Oil Mist Method Lubricant is mixed with compressed air to form an oil mist that is sprayed against the contact region of the gears. It is especially suitable for high speed gearing. Oil tank, pump, filter, piping and other devices are needed in the forced oil lubrication system. Therefore, it is used only for special high speed or large

Message

Message tel

tel Inquiry

Inquiry