Leading the way in pressure relief technology. Emerson

Leading the way in pressure relief technology. Anderson Greenwood, Crosby & Varec Pressure Direct Spring Pressure Relief Valves Safety Valves High Pilot Operated Pressure Relief Valves Low Pilot Operated Pressure Relief Valves design for medium flow of air, gas, steam, vapor, liquid and two phase applications. Full nozzle design.

Check Valves Swing Check Stop Check Lift Check

Check valves, also called as one way directional valves, are safety valves that allow gases and liquids to flow in single direction. The main purpose of check valves is to prevent the flow in reverse direction which would otherwise cause the system or equipment to

Calculator: Steam Flow Rate through a Valve TLV A

Online calculator to quickly determine Steam Flow Rate through a Valve. Includes 53 different calculations. Equations displayed for easy reference.

Pressure Relief Valve Learn about Safety Valve and

Safety valves. A safety valve is a rapid opening or pop up action pressure relief valve actuated by inlet static pressure. Safety valves are used primarily with compressible gasses. Particularly for steam and air services. Safety valves are classified according to the lift of disk and bore of the valve.

Tulsa Hatfield and Company

Solenoid Valves, Process Valve Actuation, Process Control Valves, Sensors for Level, Pressure, Flow & Fluid Analysis. Butech. High Pressure Needle Valves, Ball Valves, Subsea Valves, Fittings and Tubing Flow Switches, Pressure Switches & Transmitters, Small Solenoid Valves. High Pressure Needle Valves, Ball Valves, Subsea Valves

High Back Pressure on Pressure Safety Valves (PSVs) in a

High Back Pressure on Pressure Safety Valves (PSVs) in a Flare System Developing the Simulation model, Identifying and This thesis is focused on analyzing the back pressure build up in the high pressure Other pressure loss in fluid flow 32 3.4.1. Pressure loss coefficients 33

Check Swagelok

Check Valves. Swagelok® offers a broad line of adjustable and fixed cracking pressure check valves to control back flow in general service and high purity applications. Check valves: Are designed to allow fluids to flow in one direction only; Are rated for use in medium and high pressure applications

Low Pressure Check Valves Plast O Matic Valves, Inc.

Low Pressure Check Valves. A specialty diaphragm check valve that opens with virtually no forward pressure. However, Series CKD requires a minimum back pressure of 1/2 PSI to close. When inlet pressure is sensed the sealing disc is pushed off the valve seat opening the valve.

Control Valve Basics: Sizing and Selection CED Engineering

• MSS SP 69 for general butterfly valves • UL 1091 for safety butterfly valves for fire protection services Advantages: • Low cost and maintenance • High capacity • Good flow control • Low pressure drop Disadvantages: • High torque required for control • Prone to cavitation at lower flows

A Guide to Types of Valves MegaDepot

A Guide to Types of Valves Mar. 6, 2015. Although all valves have the same basic components and function to control flow in some fashion, the method of controlling the flow can vary dramatically. In general, there are four methods of controlling flow through a valve. However, some of the high pressure is bled to an auxiliary valve on

Check Valves Selection Guide Engineering360

Check valves are self activating safety valves that permit gases and liquids to flow in only one direction. The purpose of a check valve is to prevent process flow from reversing in the system which could damage equipment or upset the process. They are classified as one way directional valves.

Fittings/Check Valves High Pressure Company

We have developed check valves, elbows, tees and crosses for both the 100,000 and 150,000 psi systems. *Material is high tensile 316 stainless steel. Standard tubing glands and collars are furnished unless otherwise specified.

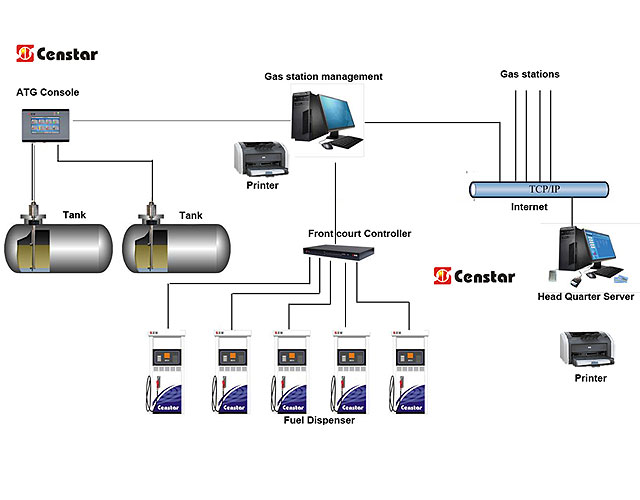

3/8 Check Valve Censtar

Find great deals on Censtar for 3/8 Check Valve in Plumbing Valves. Shop with confidence. Find great deals on Censtar for 3/8 Check Valve in Plumbing Valves. Hydraulic check valve 3/8" NPT High Pump Oil pressure single direction US. $ . Buy It Now. Free Shipping. 3 watching; Hydraulic Throttle valve check valve Flow control valve 3/8" NPT

Engineering Essentials: Pressure Control Valves

They often are used as safety valves to prevent damage to components from high surge pressures, or to relieve pressure caused by thermal expansion in locked cylinders. The differential between cracking and full open pressure on spring loaded poppet relief valves is high. For this reason they are not recommended for precise pressure control

Liquid Safety Relief Valve

Safety relief valves should not be discharged prior to installation. Do not install safety relief valves prior to pressure testing a system. If safety relief valves have been installed prior to a system pressure test, remove them. In the event there is a discharge prior or during installation the valve will need to be replaced or recertified.

Check Valve an overview ScienceDirect Topics

Check valves differ significantly from gate and globe valves. Check valves are designed to prevent backflow. Backflow simply means the flow that has reversed itself within a pipe and begins to flow backward. There are many designs of check valves, but the two most common types are the swing check and the lift check. Check valves do not use handwheels to control the flow of a commodity

Control Valves and their Principles of Operation Piping

Control valves automatically regulate pressure and/or flow rate, and are available for any pressure. If different plant systems operate up to, and at pressure/temperature combinations that require Class 300 valves, sometimes (where the design permits), all control valves chosen will be Class 300 for interchange ability.

What is check valve cracking pressure? Waverley Brownall

Miniature check valve cracking pressure 3, 5, 10, 20, 40, 60, 100, 150 Standard check valve cracking pressure 5, 15, 25, 30, 45. What is a check valve? A check valve, is a type of valve used in areas of instrumentation tubing or pipeline to control the flow of a gas or liquid.

High Pressure Globe Valve Censtar

The flow characteristics of a Globe Valve are easy to control hence flow control can be achieved at any open position. This makes the design suitable

: high pressure check valve

Control Devices Brass Ball Check Valve, 1/4" NPT Female x NPT Male. $ $ 6. 55 $ $ 14. 47. FREE Shipping on eligible orders. VA CV 5 3/8" Female Pipe High Pressure Check valve 7 PSI Cracking Pressure 5,800 PSI Max. 5.0 out of 5 stars 1. $ $ 17. 77. Kohler K 2971 KS NA High Flow Rite Temp Pressure Balancing

THE SIZING OF PRESSURE CONTROL AND PRESSURE

THE SIZING OF PRESSURE CONTROL AND PRESSURE SAFETY VALVES INCLUDING REACTION FORCE CALCULATION This case study demonstrates the use of Flownex® to size properly performing pressure control valves for typical plant operation and to size and select a code compliant matching pressure safety valve, and calculate the associated relief

Hydraulics Flashcards Quizlet

(Low pressure, high volume flow applications) Safety device for over pressure 2. Pressure limiter for max force or torque on actuator control valves and pressure relief valve must dissipate heat at rate heat is generated excessive temperature causes increased oxidation rate.

List of valves Wikipedia

Valves can be categorized into the following types, based on their operating mechanism. Ball valve, for on/off control without pressure for quick shut off, since a 90° turn completely shuts off, compared to multiple 360° turns for other manual valves.

OSHA COMPRESSED AIR SAFETY SHUT OFF VALVE

OSHA COMPRESSED AIR SAFETY SHUT OFF VALVES fails to operate despite meeting all condi SAFETY SHUT OFF VALVE is not activated the unit should be disconnected and the lower flow range OSHA COMPRESSED AIR SAFETY SHUT OFF VALVES should be used. OPERATING PRESSURE: • High air pressure rating.

In Line Mounted Flow, Pressure Control, Check and Ball

equipment can be controlled precisely, instantly, and repeatedly with Parker Control Valves. The Colorflow line includes flow control valves rated from 0 to 568 LPM (0 to 150 GPM), needle valves from 0 to 265 LPM (0 to 70 GPM), and for very accurate control, the metering valves provide linear adjustment of flows from 0 to 151 LPM (0 to 40 GPM).

how flow control valves work Censtar

Jet Fuel VS Diesel VS Gasoline how they burn and what color are they. Duration: 14:15. Just Think 4,795,938 views

High Flow Safety Valves IMI Critical

High Flow Safety Valves. 2 High Flow Safety Valves Valve summary Size DN 20 to DN 150 Set Pressure up to16 bar Protection of system components at high pressure or large mass flow, for power plants and industrial steam generators Si 6303 05 Size DN 80 to DN 300 selected where a short outlet pipe leads to the atmosphere, where the fluid

Hydraulic Valves Directional, Flow & Pressure Control

Enerpac hydraulic valves are available in a wide variety of models and configurations.Whatever your requirements; directional control, flow control, or pressure control; you can be sure that Enerpac has the correct valve to match your application exactly.Designed and manufactured for safe operation up to 10,000 psi, the range of Enerpac valves

Valve Aerodynamic Noise Reduction Strategies Valin

There are two strategies for reducing control valve noise: 1. Source control, that is doing something to the valve to make it less noisy, and 2. Path control, that is doing something to prevent the noise from reaching the people who would be bothered by it. There are two methods that are employed for source control of aerodynamic noise, pressure drop staging and flow division.

Refrigerant Valves Parker NA

Sporlan Type 3 Way series valves primary purpose is to control automatically the flow of fluids, liquid or gas. Sporlan 3 Way Valves may be applied to divert flow of

Flow and Control

Flow and Control provides Valves, Industrial Products, Pipe, Instrumentation, ANSI pump repair components and more. Call us: 800 840 1730.

SPM Flow Control Product Safety, Usage and Weir Group

The SPM® Flow Control Product Safety, Usage and Maintenance Guide is intended to provide readers with a general understanding and recommendations for the appropriate use and maintenance of SPM® flow control products. Additional information regarding the use and maintenance of

How To Prevent Freezing In Gas Pressure Reducing Systems

Hydrate formation depends on operating conditions and the gases properties, but is common in natural gas systems with high BTU content. How can I anticipate the temperature loss? Due to the Joule Thomson effect, whenever gas pressure is reduced across a control valve or regulator, its temperature is also reduced.

Valves and Piping Flashcards Quizlet

Relief/safety valves. Designed to automatically open when pressure in a system exceeds a preset limit. precise throttling to regulate fluid flow. High pressure, come shaped, needle and stem usually single piece. Opening needle valve. Flow control plug, opening in plug for fluid flow, two slips each side with seal, provided positive

Automated Dwyer Instruments

A few applications include gas or liquid flow control and mixing or diverting liquids and gases. Series WE33 Offer bubble tight shut off without leakage and withstands high pressure drops. Series WE07 150# ANSI Flange, V Ball, Electric or Pneumatic Actuators W.E. Anderson Automated Ball Valves. W.E. Anderson V Ball Valves.

Back Pressure Control Valve Equilibar

The Definition of Back Pressure Control Valves and Regulators. The term back pressure control valve and back pressure regulator are often used interchangeably. The Equilibar valves shown on this page are also referred to back pressure regulators on the rest of this site.

Vickers Check Valves Eaton

Vickers® Check Valves. 2 Introduction Vickers inline, right angle, and manifold a safety bypass for flow surges through filters and heat exchangers. With a higher spring rating, they can D*8P1 inline check valve, free flow High inertia reversing load Reciprocating motion with

Pressure Relief Valve Piping Design PIPING GUIDE

For gas, vapor, or flashing liquid service the inlet piping pressure drop at design flow should not exceed 3 percent of the safety relief valve set pressure. Nor should the inlet piping to a pressure valve be smaller than the valve inlet nominal pipe size. The inlet piping includes all piping between the protected equipment and the

Air Flow Control Valves McMaster Carr

Choose from our selection of air flow control valves, including elbow air flow control valves, air flow control valves, and more. Drain Valves Brass Needle Valves Brass Pinch Valves Brass Plug Valves Brass Pop Safety Valves Brass Pressure Regulating Valves Brass Push Button Valves Brass Relief Valves Brass Saddle Valves Brass Sleeve

Relief Valves Relief Valves Manufacturer Generant

Factory Pre Set and 100% Tested Pressure Relief Valves Generant manufactures an extensive product offering of pressure relief valves including low pressure/high accuracy and high pressure/ high flow designs. Generant pressure relief valves are relied upon in many diverse industries such as Industrial and Medical Gases, Cryogenics and Chemical Processing.

Medium and High Pressure Check Valves Swagelok

Poppet and Lift Check Valves Medium and High Pressure Check Valves (IPT Series) Ball seal poppet, soft seal poppet or dual seal ball check valves are available with working pressures up to 60 000 psig (4134 bar) and a nominal cracking pressure of 15 psi (1.0 bar) in 316 stainless steel with end connections 1/4 to 1 in. in size.

Flow Safe, Inc.

Welcome to Flow Safe FLOW SAFE is a manufacturer of High Performance pressure relief valves, both spring operated and pilot operated. Standard and custom valves are

How to Select and Size Safety Valves and Pressure Relief

Safety valves and pressure relief valves are critical for plant safety. Here are six factors that must be considered when selecting and sizing a valve. Industry News How to Select and Size Safety Valves and Pressure Relief Valves. For installations with high levels of constant back pressure, a bellows sealed valve or pilot operated

Size Matters: Control Valve Sizing 101 Industrial Automation

Size Matters: Control Valve Sizing 101. Submitted by Jon Monsen, Ph.D., P.E., Control Valve Technology Specialist at Valin the prediction of damaging levels of cavitation is more complex than simply calculating the choked flow pressure drop. As a result of flow separation and the formation of eddies within the valve, localized areas of

Maximator Valves and Fittings High Pressure Tubing

MAXPRO offers a complete line of high pressure fittings, tubing, check valves, line filters, anti vibration fittings and safety head assemblies. All high pressure valves and fittings use the high pressure style connection. Note: When selecting multiple items, the pressure rating would be

Message

Message tel

tel Inquiry

Inquiry